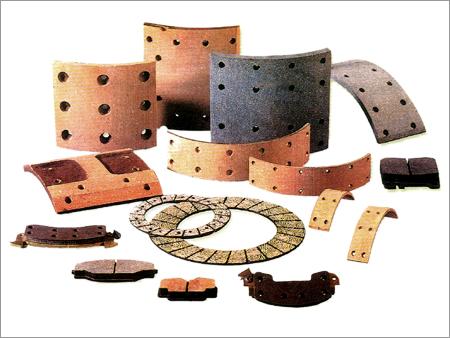

Automotive Brake Linings

Product Overview

Key Features

Company Details

Focusing on a customer-centric approach, MK AUTO CLUTCH CO. has a pan-India presence and caters to a huge consumer base throughout the country. Buy Brakes & Brake Parts in bulk from MK AUTO CLUTCH CO. at Trade India quality-assured products.

Business Type

Exporter, Manufacturer, Supplier

Employee Count

50

Establishment

1959

Working Days

Monday To Sunday

Certification

ISO 9001:2000

Seller Details

MK AUTO CLUTCH CO.

Rating

4

General Manager

Mr. A. K. Singh

Address

33-34/1653, Naiwala, Karol Bagh, New Delhi, Delhi, 110005, India

Report incorrect details

Related Products

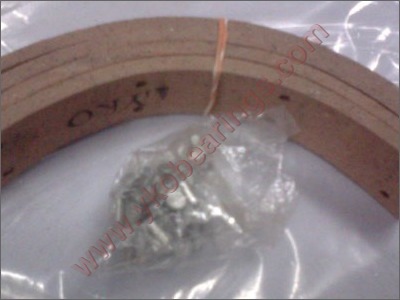

Brake Lining Roll

Price - 100-10000 INR (Approx.)

MOQ - 100 Piece/Pieces

DHINGRA SCOTWAYS

New Delhi, Delhi

Non Asbestos Bajaj Re Brake Lining

Price - 50 INR (Approx.)

MOQ - 100 Set

ARFAT AUTO INDUSTRIES

New Delhi, Delhi

Ceramic Professional Brake Lining

Price - 2000 onwards INR (Approx.)

MOQ - 1 Pair

TRIPPLE K TRADING CO.

New Delhi, Delhi

7 Inch Bch Crane Brake Lining Application: Industrial

Price - 1500 INR (Approx.)

MOQ - 1 Unit/Units

MACK SWITCHGEARS PRIVATE LIMITED

New Delhi, Delhi

More Products From This Seller

Explore Related Categories

- Tradeindia

- Brakes & Brake Parts

- Brake Lining

- Automotive Brake Linings In Karol Bagh

Recommended Products

Popular Products

Human HairForklift TrucksServo Voltage StabilizerBasmati RiceBackhoe LoaderCarry Bag Making MachineDrum LifterElectric StackerScissor LiftsIndustrial Vibrating ScreenRotameterFlowmeterRotary Air CompressorIndustrial Eto SterilizerRice Packaging MachinesShredding MachineHammer MillAutomatic Labelling MachineDiesel ForkliftAerial Work PlatformStorage Rack SystemEpoxy ResinMild Steel BarStainless Steel SheetsStainless Steel StripsBag Filling MachinesAsphalt PlantsSlat ConveyorOintment PlantPlanetary MixersLadies KurtisLed LightsCctv CameraBall ValveAnti Cancer MedicineAir CompressorIncense SticksSolar LightsGoods LiftsVitrified TilesStainless Steel CoilsPvc PipesPvc Pipe FittingsUpvc PipesUpvc Ball ValvePipe Elbows