Biomass Pellet Plant Sludge Granulation Line

Get LatestPrice

Get Best Deals

These Biomass Pellet Plant Sludge Granulation Line are preferred by means of the usage of massive amount of clients because of its immoderate exquisit...View Product Details

Product Overview

Key Features

These Biomass Pellet Plant Sludge Granulation Line are preferred by means of the usage of massive amount of clients because of its immoderate exquisite and notable capabilities.

Definition of sludge granulation line :

Sludge mixed with other materials to carry out a number of processing processes, and finally made into granule.The granules are small in size, heavy in weight and easy to store and transport. It can save energy and reduce emissions and has good economic and social benefits.Sludge pelletizing fuels can be widely used in biomass power plants, biomass steam boilers, domestic fireplaces, ovens and biomass gasifier, etc.

Raw material :

It is mainly divided into industrial sludge and domestic sludge. Industrial sludge mainly includes paper making sludge, sludge from industrial waste water treatment station, etc. Domestic sludge mainly includes river sludge, urban sewage sludge.

Flow process brief introduction :

After the sludge is dried by the paddle dryer, it is screened and finally processed for granulation. The diameter of finished particles is 6-10mm, which is optional. After cooling, the granulator is packed into 20-50kg/ bag for convenient transportation and sale. Sludge granulating project with 4 tph, the total power is about 540 kw, the workshop covers an area of 1200 a , contains raw material and finished product warehouse; The design of the whole line is compact, reasonable, meets the requirements of environmental protection, and can be customized according to customer requirements.

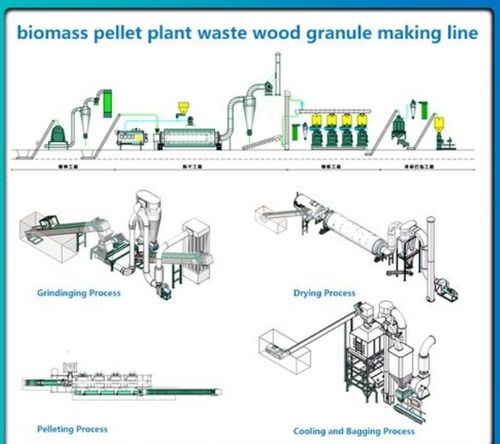

Sludge granulation project flow process :

Drying processa cleaning processa pelleting processa cooling and bagging process

Drying process:

The paddle drying system mainly includes feeding system, air preheating system, drying system, discharging system, exhaust humidity system and control system. It is used for drying sludge or sludge mixture. It is stirred by paddle, which drys evenly. Drying equipment has the characteristics of compact structure, reasonable design and large yield, etc.

Cleaning process : The purpose in the cleaning section of the complete sludge pelletizing project is to clean up the large impurities in the raw materials, so as to avoid the mechanical equipment and conveying equipment in the next process from failure or damage.The pre-screener is characterized by high output, less power consumption, simple structure, small space, easy maintenance and easy installation, etc.

Pelleting process :

4 sets of MZLH420 biomass pellet mill are designed in the pelleting process to produce 4tph biomass pellet.The diameter of biomass pellet is 6-10mm, which is optional, and the biomass pellet has the characteristics of high calorific value, no pollution and low ash content, which can be widely used in biomass power plants, biomass steam boilers, household fireplaces, drying furnaces and biomass gasifier. The complete set of sludge granulator project has obvious advantages in the pelleting process: the pellet mill is equipped with forced feeder, and the material is forced into the ring die pressing chamber, which can make the pellet operate smoothly, the material are not blocked, and produce efficiently. Specially designed arch breaking screw conveyor feeding, so that the bad fluidity material can be feeded smoothly.

Cooling and bagging process :

The cooling process of the complete set of sludge granulation project is by using of cooler to reduce particles temperature and decrease grain moisture. It is low energy consumption, easy operation and high automatic degree. The pellet after cooler is not higher than room temperature 5 a , pellet moisture after cooled is around 8-10%, particle density 650-750 kg/m3.

The bagging scale is according to th

Definition of sludge granulation line :

Sludge mixed with other materials to carry out a number of processing processes, and finally made into granule.The granules are small in size, heavy in weight and easy to store and transport. It can save energy and reduce emissions and has good economic and social benefits.Sludge pelletizing fuels can be widely used in biomass power plants, biomass steam boilers, domestic fireplaces, ovens and biomass gasifier, etc.

Raw material :

It is mainly divided into industrial sludge and domestic sludge. Industrial sludge mainly includes paper making sludge, sludge from industrial waste water treatment station, etc. Domestic sludge mainly includes river sludge, urban sewage sludge.

Flow process brief introduction :

After the sludge is dried by the paddle dryer, it is screened and finally processed for granulation. The diameter of finished particles is 6-10mm, which is optional. After cooling, the granulator is packed into 20-50kg/ bag for convenient transportation and sale. Sludge granulating project with 4 tph, the total power is about 540 kw, the workshop covers an area of 1200 a , contains raw material and finished product warehouse; The design of the whole line is compact, reasonable, meets the requirements of environmental protection, and can be customized according to customer requirements.

Sludge granulation project flow process :

Drying processa cleaning processa pelleting processa cooling and bagging process

Drying process:

The paddle drying system mainly includes feeding system, air preheating system, drying system, discharging system, exhaust humidity system and control system. It is used for drying sludge or sludge mixture. It is stirred by paddle, which drys evenly. Drying equipment has the characteristics of compact structure, reasonable design and large yield, etc.

Cleaning process : The purpose in the cleaning section of the complete sludge pelletizing project is to clean up the large impurities in the raw materials, so as to avoid the mechanical equipment and conveying equipment in the next process from failure or damage.The pre-screener is characterized by high output, less power consumption, simple structure, small space, easy maintenance and easy installation, etc.

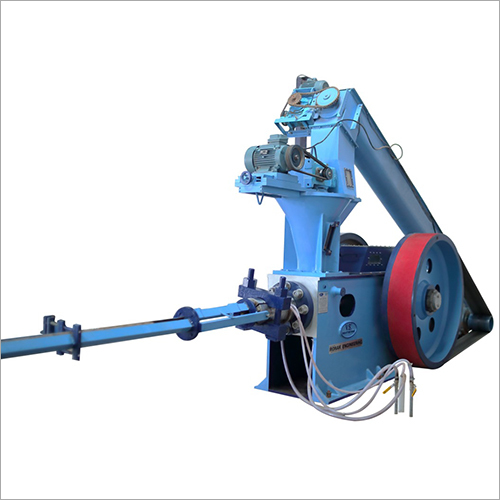

Pelleting process :

4 sets of MZLH420 biomass pellet mill are designed in the pelleting process to produce 4tph biomass pellet.The diameter of biomass pellet is 6-10mm, which is optional, and the biomass pellet has the characteristics of high calorific value, no pollution and low ash content, which can be widely used in biomass power plants, biomass steam boilers, household fireplaces, drying furnaces and biomass gasifier. The complete set of sludge granulator project has obvious advantages in the pelleting process: the pellet mill is equipped with forced feeder, and the material is forced into the ring die pressing chamber, which can make the pellet operate smoothly, the material are not blocked, and produce efficiently. Specially designed arch breaking screw conveyor feeding, so that the bad fluidity material can be feeded smoothly.

Cooling and bagging process :

The cooling process of the complete set of sludge granulation project is by using of cooler to reduce particles temperature and decrease grain moisture. It is low energy consumption, easy operation and high automatic degree. The pellet after cooler is not higher than room temperature 5 a , pellet moisture after cooled is around 8-10%, particle density 650-750 kg/m3.

The bagging scale is according to th

Company Details

Jiangsu Liangyou Renewable Energy Mechanical Engineering Co., Ltd., Established in 2003 at Changzhou in Jiangsu, is a leading Exporter,Manufacturer of Plant & Machinery in China. Jiangsu Liangyou Renewable Energy Mechanical Engineering Co., Ltd. is one of Trade India's verified and trusted sellers of listed products. With extensive experience in supplying and trading Biomass Pellet Plant Sludge Granulation Line, Jiangsu Liangyou Renewable Energy Mechanical Engineering Co., Ltd. has made a reputed name for itself in the market with high-quality Biomass Burning Wood Pellet Production Line, Biomass Pellet Plant Sludge Granulation Line, Biomass Pellet Plant Waste Wood Granule Making Line, etc.

Focusing on a customer-centric approach, Jiangsu Liangyou Renewable Energy Mechanical Engineering Co., Ltd. has a pan-India presence and caters to a huge consumer base throughout the country. Buy Plant & Machinery in bulk from Jiangsu Liangyou Renewable Energy Mechanical Engineering Co., Ltd. at Trade India quality-assured products.

Focusing on a customer-centric approach, Jiangsu Liangyou Renewable Energy Mechanical Engineering Co., Ltd. has a pan-India presence and caters to a huge consumer base throughout the country. Buy Plant & Machinery in bulk from Jiangsu Liangyou Renewable Energy Mechanical Engineering Co., Ltd. at Trade India quality-assured products.

Business Type

Exporter, Manufacturer

Establishment

2003

Seller Details

J

Jiangsu Liangyou Renewable Energy Mechanical Engineering Co., Ltd.

General manager

Mr. Zhi Liang Chen

Address

#6 Chenyang Road, Jiangsu Zhongguancun Science And Technology Industrial Park, Liyang, Changzhou, Jiangsu, 213300, China

biomass plant in ChangzhouReport incorrect details

Related Products

Briquette Making Machine Briquette Size: 90 Mm

Price - 500000 INR (Approx.)

MOQ - 1 Unit/Units

JAY KHODIYAR MACHINE TOOLS

Rajkot, Gujarat

Automatic Coffee Husk Briquetting Machine

Price - 2100000 INR (Approx.)

MOQ - 1 Plant/Plants

RONAK ENGINEERING

Rajkot, Gujarat

More Products From This Seller

Explore Related Categories

- Tradeindia

- Plant & Machinery

- Biomass Plant

- Biomass Pellet Plant Sludge Granulation Line In Liyang

Recommended Products

Popular Products

Human HairForklift TrucksServo Voltage StabilizerBasmati RiceBackhoe LoaderCarry Bag Making MachineDrum LifterElectric StackerScissor LiftsIndustrial Vibrating ScreenRotameterFlowmeterRotary Air CompressorIndustrial Eto SterilizerRice Packaging MachinesShredding MachineHammer MillAutomatic Labelling MachineDiesel ForkliftAerial Work PlatformStorage Rack SystemEpoxy ResinMild Steel BarStainless Steel SheetsStainless Steel StripsBag Filling MachinesAsphalt PlantsSlat ConveyorOintment PlantPlanetary MixersLadies KurtisLed LightsCctv CameraBall ValveAnti Cancer MedicineAir CompressorIncense SticksSolar LightsGoods LiftsVitrified TilesStainless Steel CoilsPvc PipesPvc Pipe FittingsUpvc PipesUpvc Ball ValvePipe Elbows