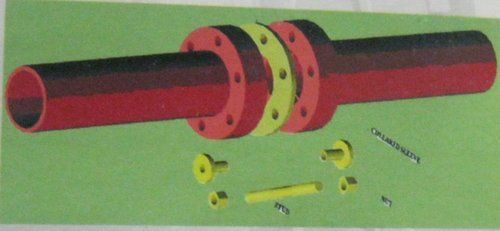

Casing Insulators

Being an ISO 9001:2008 certified and customer centric organization, we believe in providing our customers with a wide range of best quality Casing...View Product Details

Product Overview

Key Features

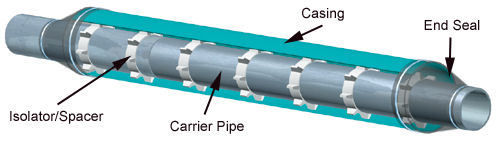

Being an ISO 9001:2008 certified and customer centric organization, we believe in providing our customers with a wide range of best quality Casing Insulators at cost effective prices. The offered insulators are used for supporting the carrier pipe from the casing pipe at the cased crossings. Owing to their excellent insulating property, these Casing Insulators are highly demanded in the market. Features: Resistant to corrosion Resistant to cold flow Optimum compressive strength The main scope of the pipeline insulator should be used to support the carrier pipe inside the casing pipe and electrically isolated the carrier pipe from the casing pipe at the cased crossings. Resist cold flow and will not soften at design temperature Resist corrosion Resist mechanical damage while being pulled into the casing. Have high electrical insulating value and low water absorption, thus preventing leakage and maintain electrical isolation between carrier and casing pipe. Have high compressive strength in order to ensure a permanent support to the carrier pipe. Casing Insulator: isolates the Carrier Pipe from the Casing Pipe. Insulator a.k.a. Isolator (or) spacer is fitted on to the OD surface of the Carrier Pipe. Casing Insulator are made in circular segments & assembled together by steel fasteners.Casing insulators are designed to support and electrically isolate a carrier pipe from its casing in order to prevent bi-metallic corrosion (Bi-metallic corrosion is a serious threat to pipelines passing through casings at railroad and highway crossings) and also to protect carrier pipe coating from damage.Casing insulators dialectically insulate gas, oil and water pipelines from casings to prevent corrosion. They also provide support to the pipeline and protect pipe coatings during installation.We recommend installation of HDPE / PP casing insulators every 3 to 8 feet depending on the site conditions & diameter of the Pipes.

Company Details

Business Type

Exporter, Manufacturer, Supplier

Employee Count

100

Establishment

1984

Working Days

Monday To Sunday

GST NO

33AAFFV1458A1ZL

Seller Details

V P ENGINEERS

GST

33AAFFV1458A1ZL

Rating

5

Managing Partner

Mr N Srinivasan

Address

8/11 Jeevanantham Street Lakshmipuram Thiruvanmiyur Chennai, Tamil Nadu, 600041, India

Cleaning Equipment in ChennaiReport incorrect details

Related Products

BSL-50 H Surface Condenser Cleaning Equipment

MOQ - 1 Unit/Units

J K ENGINEERING & TECHNOLOGY

Chennai, Tamil Nadu

Septic Tank Cleaning Chemicals

Price - 1100.00 INR (Approx.)

MOQ - 1 Kilograms/Kilograms

BUBBLE CHEMICALS

Chennai, Tamil Nadu

Floor Scrubbing Polishing And Buffing Machines

MOQ - 1 Unit/Units

Prime Power Products

Chennai, Tamil Nadu

Automatic Moon Laser Fiber Laser Cleaning Machine

Price - 1050000 INR (Approx.)

MOQ - 1 Unit/Units

MOON LASER

Chennai, Tamil Nadu

More Products From This Seller

- Tradeindia

- Cleaning Equipment

- Casing Insulators In Thiruvanmiyur

Recommended Products

Popular Products

Human HairForklift TrucksServo Voltage StabilizerBasmati RiceBackhoe LoaderCarry Bag Making MachineDrum LifterElectric StackerScissor LiftsIndustrial Vibrating ScreenRotameterFlowmeterRotary Air CompressorIndustrial Eto SterilizerRice Packaging MachinesShredding MachineHammer MillAutomatic Labelling MachineDiesel ForkliftAerial Work PlatformStorage Rack SystemEpoxy ResinMild Steel BarStainless Steel SheetsStainless Steel StripsBag Filling MachinesAsphalt PlantsSlat ConveyorOintment PlantPlanetary MixersLadies KurtisLed LightsCctv CameraBall ValveAnti Cancer MedicineAir CompressorIncense SticksSolar LightsGoods LiftsVitrified TilesStainless Steel CoilsPvc PipesPvc Pipe FittingsUpvc PipesUpvc Ball ValvePipe Elbows