Mixing Machines

(962 products)

Semi-Automatic Asafoetida Mixing Machine

Price: 75000 INR/Unit

MOQ - 1 Unit/Units

Color - Gray

Type - Asafoetida Mixing Machine

Material - Steel

3 Years

Business Type: Manufacturer | Supplier

INNOVATIVE ENGINEERING WORKS

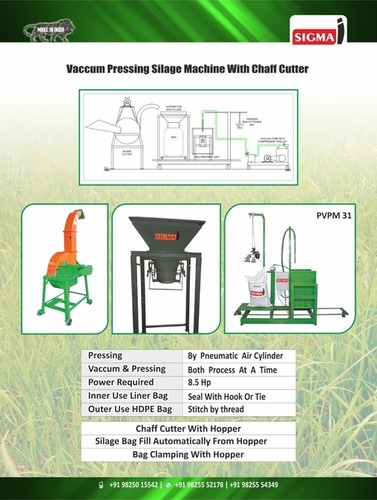

Highly Efficient Material Mixing And Packing Machine

Price: 396000 INR/Unit

MOQ - 1 Unit/Units

Type - Packaging Line

Material - Mild steel

Feature - Highly Efficient

14 Years

Business Type: Manufacturer | Exporter

SIGMA INSTRUMENTATION

Automatic Spice Mixing Machine

Price: 600000 INR/Piece

MOQ - 1 Piece/Pieces

Product Type - Automatic Spice Mixing Machine

General Use - commercial

Capacity - 1 T/hr

2 Years

Business Type: Manufacturer

PARUL ENGINEERING PRIVATE LIMITED

Green Maida Mixing Machine

Price: 1050 INR/Unit

MOQ - 1 , Unit/Units

Color - Green

Product Type - Mixing Machine

General Use - For Food Processing

13 Years

Business Type: Manufacturer | Supplier

RISING INDUSTRIES

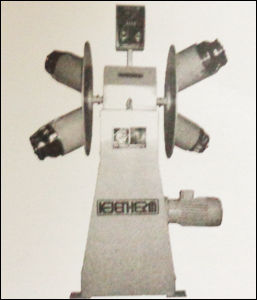

Automatic Two Rolls Mixing Mill Machine

MOQ - 1 Unit/Units

Type - Two Rolls

Material - Cast iron

Computerized - No

22 Years

Business Type: Manufacturer | Supplier

SANTEC EXIM PRIVATE LTD

New Bicarbonate Mixing Machine (Icu Machine)

Equipment Type - New Bicarbonate Mixing Machine

Condition - New

Portable - No

10 Years

Business Type: Manufacturer | Distributor

HEMANT SURGICAL INDUSTRIES LTD.

Ss Sugar Mixing Tank

Price: 105000.00 INR/Number

MOQ - 1 Number

Size - AS PER CLIENT REQUIREMENT

Length - AS PER CLIENT REQUIREMENT Millimeter (mm)

Product Type - MIXING TANK

4 Years

Business Type: Manufacturer | Supplier

CHARMI ENGINEERING

Automatic Mixture Machine

MOQ - 1 Unit/Units

Product Type - Mixture Machine

Material - Stainless Steel

Computerized - No

2 Years

Response Rate: 80.73%

Business Type: Manufacturer | Exporter

Krishna Fab Tech

Besan Mixing Machine Hotel & Restaurant

Price: 20900 INR/Piece

MOQ - 1 Piece/Pieces

Product Type - Besan Mixing Machine

General Use - Hotel & Restaurant

Material - Stainless Steel

4 Years

Response Rate: 79.55%

Business Type: Manufacturer | Distributor

UDAAN ENGINEERING

Indian Inquiries Only

Related Searches

High Efficiency Mixture Machine

Price: 80000 INR/Unit

MOQ - 1 Unit/Units

Product Type - Mixture Machine

General Use - Industrial

Automatic - Yes

2 Years

Business Type: Manufacturer | Distributor

Bhagirath Engineering Works

Semi-Automatic Drum Type Mixing Machine

Price: 75000.00 INR/Unit

MOQ - 1 Unit/Units,

Color - Silver

Type - Other

Material - Steel

16 Years

Business Type: Manufacturer | Exporter

SHREE CHAMUNDA MICRO INDUSTRIES

Shrikhand Mixing Machine Dimension(L*W*H): 32*22*38 Inch (In)

Price: 37000 INR/Piece

MOQ - 1 Piece/Pieces

Weight (kg) - 75 Kilograms (kg)

Dimension (L*W*H) - 32*22*38 Inch (in)

6 Years

Business Type: Manufacturer | Distributor

THE ONE KITCHEN EQUIPMENT

Indian Inquiries Only

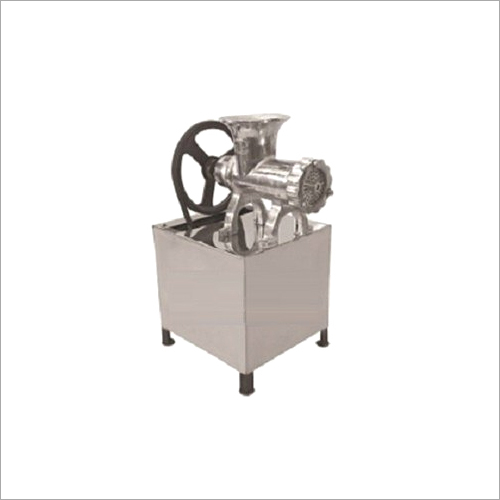

Besan Mixing Machine

Price: 38000 INR/Piece

MOQ - 1 Piece/Pieces

Color - Other

Product Type - Besan Mixer

General Use - It is used to mixing the besan

6 Years

Business Type: Manufacturer | Distributor

SONAR APPLIANCES PVT. LTD.

Mixing Machine - Feature: High Efficiency

Price: 25440 INR/Unit

MOQ - 1 Unit/Units

Color - Other, Silver

Product Type - Mixing Machine

General Use - Commercial

3 Years

Response Rate: 90.60%

Business Type: Manufacturer | Exporter

CONFIDER INDUSTRIES LLP

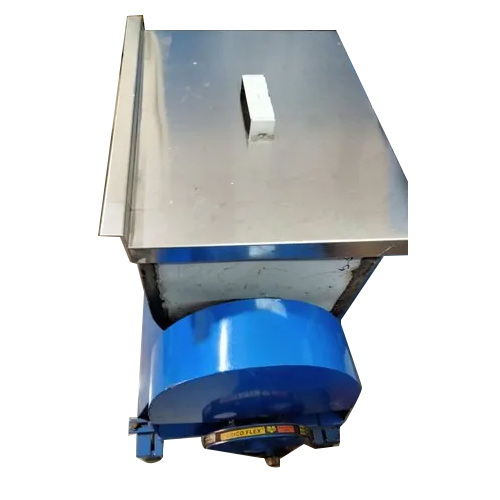

Automatic Mixture Machine Capacity: 500 Kg/Hr

Price: 25000 INR/Piece

MOQ - 1 Piece/Pieces

Color - Silver-Blue

Product Type - Automatic Mixture Machine

Material - Mild Steel

10 Years

Business Type: Manufacturer | Trading Company

DISPOSABLE MACHINERY

Online Mixing System

Price: 25000 INR/, Set

MOQ - 4 , Set/Sets

8 Years

Business Type: Manufacturer | Exporter

NEOTECH WATER SOLUTIONS

Shrikhand Mixing Machine

Price: 39000.00 INR/Unit

MOQ - 1 Unit/Units

Computerized - No

Automatic - Yes

Installation Type - Free Stand

20 Years

Response Rate: 86.22%

Business Type: Manufacturer | Distributor

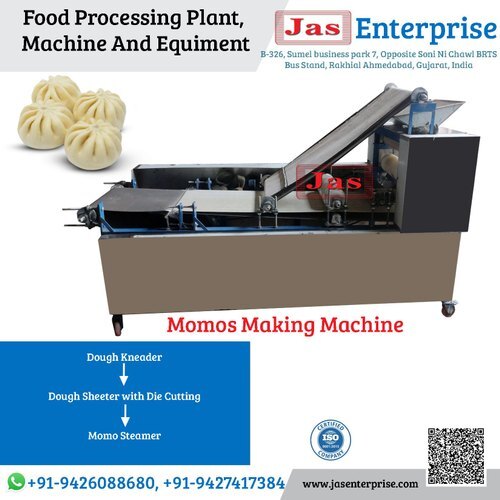

JAS ENTERPRISE

Meat Vacuum Mixing And Meat Tumbler Machine Capacity: 100Kg/Times Kg/Hr

Price Trend: 1000.00 - 5000.00 USD ($)/Set

MOQ - 1 Set/Sets

Product Type - Electric Vacuum Mixer

Material - Stainless Steel

Type - Food Processors

2 Years

Business Type: Manufacturer | Distributor

ZHAOQING FENGXIANG FOOD MACHINERY CO., LTD.

Besan Mixing Machine Capacity: 30 Kg/Hr

Price: 26000 INR/Piece

MOQ - 1 Piece/Pieces

Color - Other, Silver

Product Type - Besan Mixing Machine

General Use - Commercial

14 Years

Business Type: Manufacturer | Exporter

RAJ WORKS INDUSTRIES

Steel Namkin Coating Mixing Machine

Price Trend: 19000.00 - 65000.00 INR/Piece

MOQ - 1 Piece/Pieces

Product Type - COATING & MIXING

General Use - Food Preparation

Material - Stainless Steel

4 Years

Business Type: Manufacturer | Exporter

PRAGATI ENGGINEERS

All About Mixing Machines:

Mixing machines are modern day mandatory requirement to blend or mix many different items for specific purposes. We are familiar with mixing machines or mixers at home when we work with spices, fruits and other food items. However, there are mixing machines that are bigger in size and functionality and they are mainly used for commercial purpose when the items are in bulk. Such machines include snacks mixing machine, detergent mixing machine, maida mixing machine, stainless steel flour mixing machine, pharmacy powder mixing machine, colour mixing machine and tea mixing machine. All these mixing machines carry individual application. Then, we have used granule mixing machine, paste mixing machine and dough mixing machine. In usage and prices, these machines vary, but all these machines carry applications in commercial setting or used for business purposes.

Mixing machines are very useful machines in many different settings and purposes to grind and mix two or more food items, pharmacy items, or colours or concrete items. From mixing flour to industrial concrete mixers to spice mixers, mixing machines are vital devices today for industrial, commercial and personal uses and applications. If the colour mixing machine is meant to prepare colour mixture for painting purposes, detergent powder mixing machine help mix detergent items for soap-making. If we find different types of tumbling mixers, we can have Y-cone mixer, rotating cube, V-shaped, cylindrical, and double-cone mixer. All the mixing machines serve special purpose in their respective industrial applications.

Applications of Mixing Machine:

Different mixing machines serve different purposes in mixing and blending various items in many different industries. The mixing machines cover the industries such as pharmaceutical industry, dyes industry, chemicals industry, construction industry, food industry, organics industry, pigments industry, and agricultural industry.

Buyers desirous of purchasing the Mixing Machines in bulk quantity and in different technical specifications may check the details of all the available products here. Our registered sellers will provide the best deals at most competitive prices.

The advantages of using different types of mixing machinery?

There are several types of mixing machinery used in various industrial applications, including:

Planetary Mixers: A versatile type of mixer that can handle a wide range of applications, including baking, confectionery, and pharmaceuticals. They consist of a central agitator that rotates on its own axis while also orbiting around a fixed point.

Ribbon Mixers: Used in the food and chemical industries, these mixers consist of two parallel horizontal shafts with ribbon-shaped blades. They are designed to mix dry powders and granules effectively.

Agitator Mixers: These mixers are used for blending liquids and suspending solids in the chemical and pharmaceutical industries. They consist of a rotating shaft with attached blades that create turbulence in the mixture.

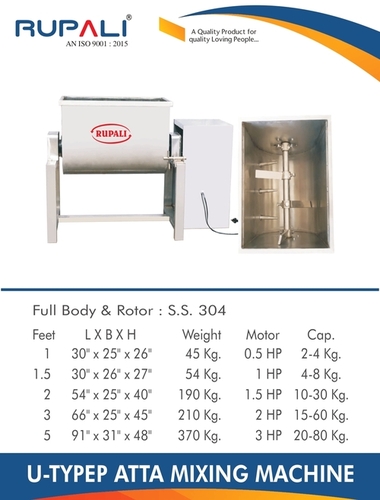

Dough Mixers: Used in the baking industry, these mixers are specifically designed for mixing dough ingredients. They come in various sizes and capacities, from small tabletop models to large commercial models.

High-Shear Mixers: These mixers use high-speed blades to emulsify and homogenize liquids in the chemical and pharmaceutical industries. They are often used for mixing viscous liquids and for particle size reduction.

Dual Shaft Mixers: Used in the production of adhesives, sealants, and other materials, these mixers consist of two rotating shafts with attached blades that mix the materials thoroughly.

Twin-Shell Mixers: Used in the chemical and food industries, these mixers consist of two concentric, vertically-oriented cylinders. They are designed for blending and mixing powders and pastes.

Each type of mixing machinery is designed and manufactured for specific applications and has its own unique features and benefits.

Future Trends in Mixing Machines:

- Automation and digitalization

- Energy efficiency and sustainability

- Customization and versatility.

Choose the right mixing machine for your application?

Choosing the right mixing machine for your application involves considering several factors, including the properties of the materials you will be mixing, volume, mixing requirements, speed, environment, cleaning/maintenance, and budget. Here are some key points to consider:

Material properties: Consider viscosity, density, particle size, reactivity, and sensitivity to temperature and pressure of the materials you will be mixing.

Volume: Consider the volume of material you need to mix and choose a mixer with appropriate capacity.

Mixing requirements: Determine the type of mixing you will be performing and choose a mixer with the right capabilities, such as homogenizing, emulsifying, or simply blending.

Speed: High speed mixing requires a powerful mixer, while lower speed mixing can be performed with a gentler mixer.

Environment: Consider temperature, pressure, and hazardous materials in the mixing environment to choose a mixer that can safely operate in that environment.

Cleaning and maintenance: Choose a mixer that is easy to clean and maintain to ensure its longevity and performance over time.

Budget: Consider your budget and choose a mixer that offers the right balance of features and performance within your budget constraints.

Consulting with an expert in mixing technology can help you choose the right mixer for your application.

Advantages of Mixing Machines:

- Improved product quality

- Increased production efficiency

- Uniform mixture

Techniques used in Mixing Machines:

- Stirring

- Shaking

- Blending

FAQs: Mixing machine

Q. How many types of mixture machines are there?

Ans. There are several types of mixing machines, including:

- Mechanical mixers

- Magnetic mixers

- Dynamic mixers

- Vacuum mixers

- Planetary mixers

- Ribbon mixers

- Paddle mixers

- Stirrers and agitators

- High-shear mixers

- Static mixers

Q. What is the application of concrete mixture?

Ans. Concrete mixture is used as a building material in construction and has many applications, including foundations, bridges and roads, dam construction, walls and partitions, flooring and paving, and decorative and ornamental surfaces.

Q. What is a paint mixing machine and its benefits?

Ans. Paint mixing machinery refers to the equipment used for blending and homogenizing the various components that make up a paint product, such as pigments, resins, solvents, and additives. This can include various types of mixers, such as planetary mixers, high-speed dispersers, and horizontal mixers. The goal of paint mixing machinery is to produce a consistent and uniform paint product with the desired color and texture.

Q. What is a drum type mixer?

Ans. A drum type mixer is a machine for blending and homogenizing materials, typically paint components, by rotating a cylindrical drum.

Q. What are industrial mixers?

Ans. Industrial mixers are equipment used for mixing and blending various materials in industrial processes. They are used in a wide range of industries, such as food and beverage, pharmaceutical, chemical, and cosmetic manufacturing. Industrial mixers can come in different types, such as ribbon blenders, agitators, planetary mixers, and drum type mixers.

Client Testimonials & Reviews

Mixing Machines Price List

This Data was Last Updated on 2024-10-14

Mixing Machines Manufacturers | Suppliers in India

| Company Name | Location | Member Since |

|---|---|---|

| Santec Exim Private Ltd | Gurugram, India | 22 Years |

| Jas Enterprise | Ahmedabad, India | 20 Years |

| Aksar Food Machine Llp | Surendranagar, India | 16 Years |

| Shree Chamunda Micro Industries | Ahmedabad, India | 16 Years |

| Sigma Instrumentation | Ahmedabad, India | 14 Years |

| Raj Works Industries | Indore, India | 14 Years |

| Devika Industries Inc | Rajkot, India | 14 Years |

| Rising Industries | Kolkata, India | 13 Years |

| M. M. Industries | Rajkot, India | 11 Years |

| Hemant Surgical Industries Ltd. | Mumbai, India | 10 Years |

FAQs Related to Mixing Machines

In the double cone

blender drum of the tea mixing machine, tea material is put into the drum. In

the double cone blender drum, tea is spread out and upon running the process of

machine, mixing is accomplished in about 20 minutes.

The cream mixing

machine is well-designed machine that works seamlessly in order to blend

viscous cream mixtures. Depending upon the size of the machine and the

materials, cream mixing machine works faster and obtains the desired

consistency and particle size that is required.

Paste mixing is

the mixing of three types: solid with solid, solid with liquid, and liquid with

liquid. The different ingredients of different densities are used in different

proportions for machine to prepare the right paste. The good part of this

machine is that it is a non-contaminating mixer.

A tumbling mixer

is a mixing device that contains a stainless steel metallic vessel. This vessel

tends to rotates about an axis either by an electricity-run motor or manually.

The highlight of the tumbling machine is its power of diffusion mechanism.

Diffusive mixing

works by rolling down when the solid particles move along with it. Much of its

working is similar to what a tumbling machine does.

- Tradeindia

- Machineries

- Mixing Machines

Related Categories

Popular Products

Human HairForklift TrucksServo Voltage StabilizerBasmati RiceBackhoe LoaderCarry Bag Making MachineDrum LifterElectric StackerScissor LiftsIndustrial Vibrating ScreenRotameterFlowmeterRotary Air CompressorIndustrial Eto SterilizerRice Packaging MachinesShredding MachineHammer MillAutomatic Labelling MachineDiesel ForkliftAerial Work PlatformStorage Rack SystemEpoxy ResinMild Steel BarStainless Steel SheetsStainless Steel StripsBag Filling MachinesAsphalt PlantsSlat ConveyorOintment PlantPlanetary MixersLadies KurtisLed LightsCctv CameraBall ValveAnti Cancer MedicineAir CompressorIncense SticksSolar LightsGoods LiftsVitrified TilesStainless Steel CoilsPvc PipesPvc Pipe FittingsUpvc PipesUpvc Ball ValvePipe Elbows