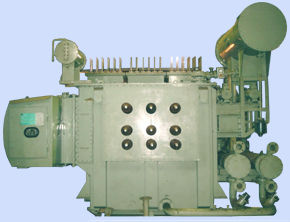

Current Conductive Electrode Cross Arm For Electric Arc Furnace And Ladle Refining Furnace Application: Copper + Steel

Price Trend: 2000-10000 USD / Set

| Product Type | Current conductive electrode cross arm |

| Weight | 30 T Kilograms (kg) |

| Usage | Machinery Repair Shops, Manufacturing Plant |

| Condition | New |

| Power | 12000kw Watt (w) |

Product Overview

Key Features

Electric Arc Furnace

The three-phase AC steel-making electric arc furnace uses high temperature generated by electrode arc to melt metal. It can effectively remove sulfur, phosphorus and other impurities during the smelting process. The furnace temperature is easy to control and the equipment covers a small area. It is used for smelting ordinary steel, high-quality carbon steel, stainless steel, various alloy steels and other special steels. The three-phase steel-making electric furnace is divided into ordinary power, high power and ultra-high power according to the matching. HANI Company mainly produces electric arc furnaces with a capacity from 1.5 tons to 150 tons (DC furnace to 60 tons). Its transformer capacity can be equipped with ordinary power (RP), high power (HP) and ultra high power (UHP) levels The tapping methods include tapping of the saw tip and tapping of the eccentric bottom EBT.

Including:

1 Furnace body

2 Tilting mechanism

3 Furnace cover

4 Furnace bracket

5 Furnace cover lifting and rotating mechanism

6 Electrode lifting mechanism

7 Short Net System

8 Cooling system

9 air compression system

10 Upright bracket

11 Maintenance platform

12 platform

13 Electrode extension device

14 Hydraulic system

15 Transformer

6 Furnace door oxygen lance device

17 Furnacecluster oxygen lance

18 High voltage cabinet

19 Low voltage power supply system

20 Computer and PLC control system

Product Specifications

| Product Type | Current conductive electrode cross arm |

| Weight | 30 T Kilograms (kg) |

| Usage | Machinery Repair Shops, Manufacturing Plant |

| Condition | New |

| Power | 12000kw Watt (w) |

| Voltage | 9000KVA Volt (v) |

| Application | copper + steel |

| FOB Port | shanghai china |

| Payment Terms | Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Delivery Point (DP) |

| Supply Ability | 100 Per Month |

| Delivery Time | 120 Days |

| Sample Available | Yes |

| Sample Policy | Free samples available with shipping and taxes paid by the buyer |

| Packaging Details | PackingTotal number cartons: To be informed laterTotal volume of cartonsTotal weight of cartonsPacking is given as reference,Plycase woodSubject to change at time of delivery |

| Main Export Market(s) | Middle East, Africa, Asia |

Company Details

The company was established in 2012 years, investment by SEMC Group the famous brand is SEMC,all electric motor ,metallurgy machinery payment and import and export by chinese State-owned enterprise . We are specializing in the produce kinds of AC & DC motors Premium efficiency motor,Explosion-proof motor, NEMA motor, IEC motor , high voltage motor; Our metallurgical equipment and electric motors are exported to the United States, Mexico, Argentina, America, Iran, Iraq, the Middle East, Africa, Asia, Turkey, Russia, Uzbekistan, etc. Wlecome visiting ! Design, manufacturer and installation of metallurgical equipment and AC and DC motors and relation steel mill equipment. 1. Z Z2 Z4 ZZJ DC motor, YRKK YKK YKS AC motor,NEMA motor,High-voltage three-phase asynchronous squirrel cage induction motor and synchronous motor(500KW, 1250KW, 5000KW 15000KW 50000KW,100MW ) 2. Medium frequency induction furnace (10 tons 20 tons, 30 tons 50 tons and maximum 80 tons 30,000 KW) AC arc furnace, DC arc furnace, electroslag remelting furnace, submerged arc furnace. Alloy steel billet continuous casting machine (R5.25 m, R6 m, R9 m, R12 m R14 m ) Production of 50mm-150mm-240mm-1500mm billet) Morgan Rolling mill, short-stress rolling mill, universal rolling mill production of steel bar flat steel H-beam (100,000 tons, 300,000 tons, 500,000 tons, 1 million tons) 3. Furnace Transformer,cooling tower,de-dust machine of furnace,Rolling mill ,TMT Quenching Machine Flying shear Step cooling bed , Fiber Laser Cutting Machine,forklift and relation requipment for steel mill . 4. Power plant 5MW,320MW,760MW,1000MW 1500MW.....

Business Type

Exporter, Manufacturer, Distributor, Supplier

Employee Count

1000

Establishment

2010

Working Days

Monday To Sunday

Seller Details

Shanghai Electric Heavy Machinery Co., Ltd

Rating

4

Manager

Mr Robin Yan

Address

B No. 135, Guowei Road, Yangpu District, Shanghai, Shanghai, 200041, China

arc melting furnace in ShanghaiReport incorrect details

Related Products

Metal Three Phase Oil Cooled Submerged Arc Melting Furnace Transformer For Industrial Use

Makpower Trans Systems Pvt. Ltd.

Howrah, West Bengal

Durable Arc Melting Furnace

MOQ - 1 Piece/Pieces

SIMCO GLOBAL TECHNOLOGY & SYSTEMS LTD.

New Delhi, Delhi

Plasma Arc Melting Furnace (Pam) Application: Floor Tiles

Seco Warwick Allied Pvt. Ltd.

Navi Mumbai, Maharashtra

More Products From This Seller

Explore Related Categories

- Tradeindia

- Furnace Manufacturers

- Arc Melting Furnace

- Current Conductive Electrode Cross Arm For Electric Arc Furnace And Ladle Refining Furnace In Yangpu District

Recommended Products

Popular Products

Human HairForklift TrucksServo Voltage StabilizerBasmati RiceBackhoe LoaderCarry Bag Making MachineDrum LifterElectric StackerScissor LiftsIndustrial Vibrating ScreenRotameterFlowmeterRotary Air CompressorIndustrial Eto SterilizerRice Packaging MachinesShredding MachineHammer MillAutomatic Labelling MachineDiesel ForkliftAerial Work PlatformStorage Rack SystemEpoxy ResinMild Steel BarStainless Steel SheetsStainless Steel StripsBag Filling MachinesAsphalt PlantsSlat ConveyorOintment PlantPlanetary MixersLadies KurtisLed LightsCctv CameraBall ValveAnti Cancer MedicineAir CompressorIncense SticksSolar LightsGoods LiftsVitrified TilesStainless Steel CoilsPvc PipesPvc Pipe FittingsUpvc PipesUpvc Ball ValvePipe Elbows