Desulfurization Wastewater Treatment Plant

Accepts only Foreign inquiries

Price: 4000 USD

| FOB Port | Qingdao |

| Payment Terms | Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Western Union |

| Supply Ability | 5000 Tons Per Day |

| Delivery Time | 30 Days |

| Sample Available | Yes |

Product Overview

Key Features

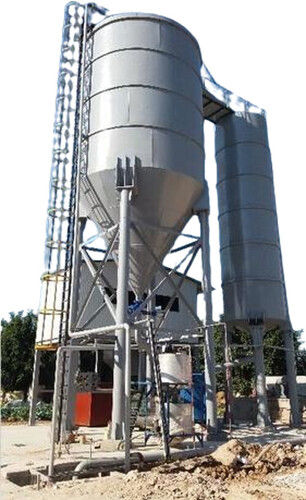

Desulfurization wastewater zero discharge process is aimed at thermal power plant desulfurization wastewater characteristics, through the softening, MVR evaporation, crystallization and other technical means to achieve high salinity desulfurization wastewater zero emission requirements, and ultimately see the formation of pure reusable distilled water and crystalline salt.

Desulfurization wastewater first into the pre-clear pool, to clarify the sediment, reducing raw water turbidity. The precipitate is discharged to the sedimentation concentrate tank and the supernatant enters the triple tank reactor. The contents of Mg2 +, Ca2 + and heavy metal ions in the reaction wastewater were Ca (OH) 2, Na2CO3 and flocculant. The desulfurization wastewater after the reaction flows into the clarification tank, and the flocs in the wastewater are precipitated to the bottom of the tank and discharged to the sedimentation and concentration tank. The supernatant flows into the middle pool and is filtered through the multi-media to enter the clean water tank and the pH The The sludge slurry is further concentrated in the sedimentation and concentration tank, and the sludge is separated into the sludge dewatering machine. After the dehydration, the sludge is transported to the off-site treatment. The sewage is recirculated through the buffer pool.

Zero - Depth Treatment Process of Desulfurization Wastewater

MVR is "mechanical vapor recompression" in English abbreviation (Mechanical Vapor Recompression). The basic principle is that the secondary steam produced during the evaporation process is mechanically recompressed, the secondary steam temperature, the pressure increase, the enthalpy increase, and then into the heat exchanger condensation, the secondary steam latent heat is fully utilized.

Henan Huatai Environmental engineering Co.,LTD. is a wholly-owned subsidiary of Henan Huatai Grain and Oil Machinery Co., Ltd., located in Henan Huaxian Industrial Zone. The company covers an area of 100,000 square meters and has 280 employees. It is a research and development, Manufacturing, installation as one of the high-tech environmental equipment manufacturing enterprises, the company and China's large and medium-sized institutions to establish technology research and development cooperation, the introduction of waste pyrolysis technology, the successful development of complete sets of living garbage pyrolysis technology, waste rubber tire heat Solution processing technology, sludge pyrolysis technology, and master the core pyrolysis furnace patented manufacturing technology. Research and development of industrial wastewater treatment, the successful development of the cellulose industry, resin industry, coal chemical industry, zero discharge of industrial wastewater engineering technology, with multi-effect evaporation crystallization, MVR evaporation crystal complete sets of engineering core technology, energy saving, efficient, non-scaling, New environmentally friendly evaporator technology.

Company Details

Henan Huatai Cereals And Oils Machinery Co.,Ltd. was founded in 1950,whcih is a large-scale oil machinery manufacturing enterprise integrating R & D, design, manufacture and installation as one of the major grain and oil machinery manufacturing enterprises in China.Our company headquartered located in Huaxiang County Industries,Henan Province,China,covering 100,000.00 square meters. Huatai machinery has developed projects including large scale oilseed pretreatment and pressing, oil extraction, oil refining and oil fractionation production line project,conveyor equipment project,corn/maize flour, grits, germ milling machines and corn processing lines,biodiesel technology,cottonseed, rice bran and soybean protein technology, and Palm Oil processing lines,etc. One of the most largest Cooking oils factory in China. Production of grain and oil equipment solutions from A to Z. Huatai is a factory with more than 60 years experience. More than 100,000 square meters. Over 580 professional employees. 8 Large-scale workshop, 120 production equipments. Henan Huatai Cereals And Oils Machinery Co.,Ltd is committed to R&D of new efficient oil machines, manufacturing customer oriented oil machines, and leading the development direction of the world's most advanced grain processing machines and oil processing machines. We are reply on technology and innovation, constantly developing new type oil machines and equipment in order to achieve worlds advanced level.

Business Type

Exporter, Manufacturer, Distributor, Supplier, Trading Company

Employee Count

500

Establishment

1950

Working Days

Monday To Sunday

Certification

ISO9001, SGS

Seller Details

HENAN HUATAI CEREALS AND OILS MACHINERY CO.,LTD.

Rating

5

Manager

Ms Dora

Member Since

5 Years

AddressView on Map

B26 No.1, Cuizhu Street High-Tech Zone, Zhengzhou, Henan, 450000, China

Report incorrect details

Related Products

C017 Chelating Resin For Electroplating Industry Wastewater Treatment Cas No: Gb13659-2008

Price - 1.6 USD ($) (Approx.)

MOQ - 100 Liter/Liters

Henan Comcess Industry Co., Ltd.

Anyang, Henan

Industrial Wastewater Treatment Services

Price - 3000 INR (Approx.)

MOQ - 1 Piece/Pieces

TERRAQUAER VENTURE PVT. LTD.

Ahmedabad, Gujarat

Effluent Treatment Plant Power Source: 1 Kw

MOQ - 1 Piece/Pieces

PURE WATERTECH PVT. LTD.

Sonipat, Haryana

Industrial Wastewater Treatment Plant 2, Voltage (V): 380 V

INDIAN ION EXCHANGE & CHEMICALS LTD.

Ahmedabad, Gujarat

Wastewater Treatment System

Price - 200000.00 INR (Approx.)

MOQ - 1 Unit/Units

K-PACK SYSTEMS PRIVATE LIMITED

Bengaluru, Karnataka

Industrial Wastewater Treatment

MOQ - 1 Unit/Units

Sun Disinfection Equipment'S And Systems

Pune, Maharashtra

A Grade 100 Percent Purity Good Quality Finely Grounded Blended Ferric Sulphate

Price - 75 INR (Approx.)

MOQ - 500 Kilograms/Kilograms

CNYWAT GROUP

Wuxi, Jiangsu

Industrial Wastewater Treatment Chemicals - Physical Form: Liquid

Price - 600 INR (Approx.)

MOQ - 1 Ton/Tons

YIXING BLUWAT CHEMICALS CO., LTD.

Yixing, Jiangsu Sheng

Industrial Wastewater Treatment Plant

Price - 100000 - 10000000 INR (Approx.)

MOQ - 1 Piece/Pieces

KINGS INDUSTRIES

Coimbatore, Tamil Nadu

Blue Industrial Wastewater Treatment Plant

Price - 250000.00 INR (Approx.)

MOQ - 1 Set/Sets, Set/Sets, Set/Sets

CONSTRARCH ENVIRO

Moradabad, Uttar Pradesh

Semi Automatic Industrial Wastewater Treatment Plant

Price - 500000 INR (Approx.)

MOQ - 1 Unit/Units

DHARA WATER TECH PRIVATE LIMITED

Pune, Maharashtra

Industrial Wastewater Treatment Plant - Capacity: 11000 M3/Hr

Price - 175000 INR (Approx.)

MOQ - 1 Unit/Units

SWATI WATER PURIFICATION

Ahmedabad, Gujarat

More Products From This Seller

Explore Related Categories

- Tradeindia

- Commercial Service

- Industrial Wastewater Treatment

- Desulfurization Wastewater Treatment Plant In Cuizhu Street High-tech Zone

Recommended Products

Popular Products

Human HairForklift TrucksServo Voltage StabilizerBasmati RiceBackhoe LoaderCarry Bag Making MachineDrum LifterElectric StackerScissor LiftsIndustrial Vibrating ScreenRotameterFlowmeterRotary Air CompressorIndustrial Eto SterilizerRice Packaging MachinesShredding MachineHammer MillAutomatic Labelling MachineDiesel ForkliftAerial Work PlatformStorage Rack SystemEpoxy ResinMild Steel BarStainless Steel SheetsStainless Steel StripsBag Filling MachinesAsphalt PlantsSlat ConveyorOintment PlantPlanetary MixersLadies KurtisLed LightsCctv CameraBall ValveAnti Cancer MedicineAir CompressorIncense SticksSolar LightsGoods LiftsVitrified TilesStainless Steel CoilsPvc PipesPvc Pipe FittingsUpvc PipesUpvc Ball ValvePipe Elbows