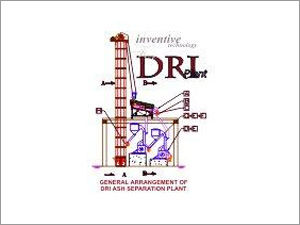

Dri Ash Plant

Get LatestPrice

Get Best Deals

Leveraging

on our vast industry experience, we are manufacturing, exporting and

supplying a finest quality range of

Dri

Ash Plant.

Product Overview

Key Features

Leveraging

on our vast industry experience, we are manufacturing, exporting and

supplying a finest quality range of

Dri

Ash Plant.

The provided plant is precisely tested on different quality

parameters by our highly skilled quality inspectors to ensure its

flawless delivery at clients' end. This plant is used for the air

separation of solids and to separate the carbon bearing char from the

magnetic and non-magnetic oxide wastes. Our professionals manufacture

this plant by utilizing the optimum quality components and the

ultra-modern technology as per the international quality standards.

Besides, this Dri

Ash Plant

is offered at highly affordable rates to our clients.

Features:

High strength

Strong constructionLow maintenanceAnti-corrosive

SCOPE OF DRI ASH SEPARATION PLANT:

Sponge

Iron is iron ore reduced directly in solid state using coal gas,

natural gas or coal as reductants and is also known as Directly Reduced

Iron(DRI). The need for development and commercialization of sponge iron

manufacturing process arose in late 50's when Electric Arc Furnaces

(EAFs) engaged in manufacturing steel started facing problems of

availability of scrap of desired quality, the traditional source of

their iron metallics. The DRI process soon become popular and since the

inception of first DRI plant in 1957 in Mexico, there has been

continuous growth of this industry in last three decades. This is

evident from the steep rise in world DRI production during the past

three decades. India entered the sponge Iron industry only in 1980, when

the coal based DRI plant of Sponge Iron India Limited (SIIL) was

commissioned at Kothagudem, in Andhra Pradesh.

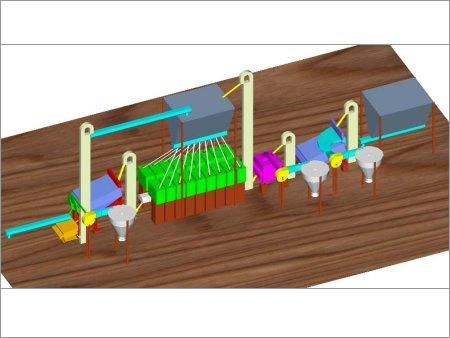

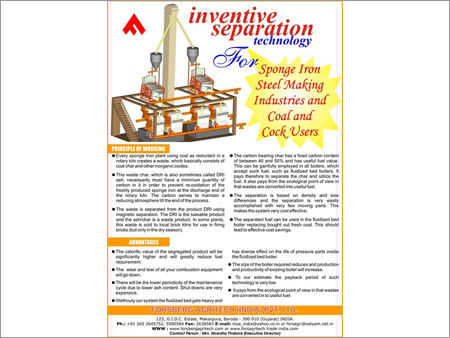

PRINCIPLE OF WORKING:

Every

sponge Iron plant using coal as reductant in a rotary kiln creates a

waste, which basically consists of coal char and other inorganic oxides.

This

waste char, which is also sometimes called DRI ash, necessarily must

have a minimum quantity of carbon in it in order to prevent re-oxidation

of the freshly produced sponge iron at the discharge end of the rotary

kiln. The carbon serves to maintain a reducing atmosphere till the end

of the process.

The

waste is separated from the product DRI using magnetic separation. The

DRI is the saleable product and the ash/char is a waste product. In some

plants, this waste is sold to local brick kilns for use in firing

bricks (but only in the dry season).

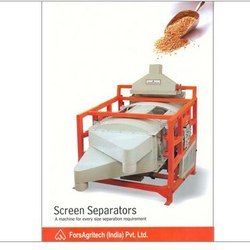

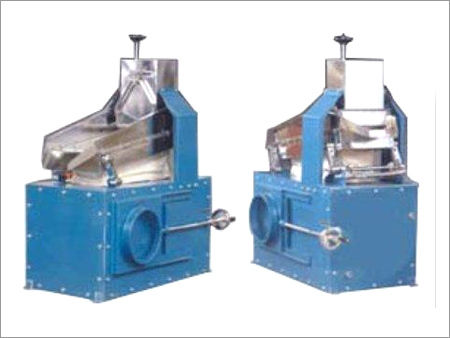

Forsberg Agritech builds

machines for air separation of solids and one such machine can be used

to separate the carbon bearing char from the magnetic and non-magnetic

oxide wastes.

The

carbon bearing char has a fixed carbon content of between 40 and 50%

and has useful fuel value. This can be gainfully employed in all

boilers, which accept such fuel, such as fluidized bed boilers. It pays

therefore to separate the char and utilize the fuel. (The waste could be

used directly but will have lower calorific value and will make the

fluidized bed heavy which can have adverse effect on the life of the

pressure parts inside the fluidized bed boiler.) It also pays from the

ecological point of view in that wastes are converted into useful fuel.

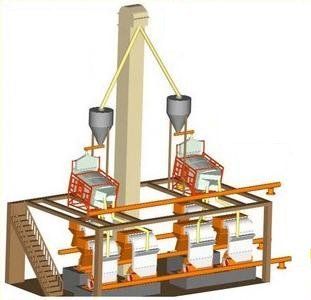

The

separation is based on density and size differences and the separation

is very easily accomplished with very few moving parts. This makes the

system very cost effective.

The

separated fuel can be used in the fluidized bed boiler replacing bought

out fresh coal. This should lead to effective cost savings.

As

the plant is not compatible with wet ash it is proposed that wetting in

pug mill be eliminated and the dry material be fed to our plant through

closed conveying system e.g. screw conveyor with an automatic bag

filter system.

ADVANTAGES:

The

calorific value of the segregated product will be significantly higher

than that of the total DRI ASH, - which is being currently used. The

recovered high calorific carbon will greatly reduce fuel requirement.When

the Ash content goes down and percentage of FC that goes in the boiler

increases the wear and tear of all your combustion equipment will go

down. One will be the best judge to estimate the saving that one may be

able to achieve due to lower wear and tear of the equipment due to lower

ash content.A

related saving will be the lower periodicity of the maintenance cycle

due to lower ash content. Again it will vary from z place to place. One

will immensely gain in down time. Shut downs are very expensive.Even

if 42 to 50 % available FC is collected and gainfully employed in all

Boilers, it pays to separate the Char and use the fuel. In the bargain

this reduces the disposable Ash and increase the calorific value of the

fuel in the Boiler.The

waste, when used directly (as is being done presently) with less

calorific value makes the fluidized bed heavy which can have adverse

effect on the life of pressure parts inside the fluidized bed boiler.It pays from the ecological point of view in that wastes are converted in to useful fuel.When

there is less ash % going in to the boiler, the size of the boiler

required reduces and your total cost of boiler will comedown or

production and productivity of existing boiler will increase.To our estimate the payback period of such technology is very low.

Explore in hindi - ड्री ऐश प्लांट

Company Details

FORSBERG AGRITECH (INDIA) PVT. LTD., Established in 1992 at Vadodara in Gujarat, is a leading Exporter,Manufacturer,Supplier of Seed Processing Machinery in India. FORSBERG AGRITECH (INDIA) PVT. LTD. is one of Trade India's verified and trusted sellers of listed products. With extensive experience in supplying and trading Dri Ash Plant, FORSBERG AGRITECH (INDIA) PVT. LTD. has made a reputed name for itself in the market with high-quality Color Sorter, DRI-Ash Plant, Destoner, etc.

Focusing on a customer-centric approach, FORSBERG AGRITECH (INDIA) PVT. LTD. has a pan-India presence and caters to a huge consumer base throughout the country. Buy Seed Processing Machinery in bulk from FORSBERG AGRITECH (INDIA) PVT. LTD. at Trade India quality-assured products.

Focusing on a customer-centric approach, FORSBERG AGRITECH (INDIA) PVT. LTD. has a pan-India presence and caters to a huge consumer base throughout the country. Buy Seed Processing Machinery in bulk from FORSBERG AGRITECH (INDIA) PVT. LTD. at Trade India quality-assured products.

Business Type

Exporter, Manufacturer, Supplier

Employee Count

40

Establishment

1992

Working Days

Monday To Sunday

GST NO

24AAACF3360M1ZP

Seller Details

F

FORSBERG AGRITECH (INDIA) PVT. LTD.

GST

24AAACF3360M1ZP

Managing Director

Mrs. Nivedita A. Thakore

Address

Plot No 123, GIDC Estate, Makarpura, Near Ajay Engineering Company Vadodara, Gujarat, 390010, India

Seed Processing Machinery in VadodaraReport incorrect details

Related Products

Automatic Gto2N Seed Processing Machinery

Price - 18500 INR (Approx.)

MOQ - 1 Unit/Units

GOREK TECHNOLOGIES

Surat, Gujarat

Silver Gto2N Seed Processing Machinery

Price - 18500 INR (Approx.)

MOQ - 1 Unit/Units

GOREK TECHNOLOGIES

Surat, Gujarat

More Products From This Seller

- Tradeindia

- Seed Processing Machinery

- Dri Ash Plant In Makarpura (Vdr)

Recommended Products

Popular Products

Human HairForklift TrucksServo Voltage StabilizerBasmati RiceBackhoe LoaderCarry Bag Making MachineDrum LifterElectric StackerScissor LiftsIndustrial Vibrating ScreenRotameterFlowmeterRotary Air CompressorIndustrial Eto SterilizerRice Packaging MachinesShredding MachineHammer MillAutomatic Labelling MachineDiesel ForkliftAerial Work PlatformStorage Rack SystemEpoxy ResinMild Steel BarStainless Steel SheetsStainless Steel StripsBag Filling MachinesAsphalt PlantsSlat ConveyorOintment PlantPlanetary MixersLadies KurtisLed LightsCctv CameraBall ValveAnti Cancer MedicineAir CompressorIncense SticksSolar LightsGoods LiftsVitrified TilesStainless Steel CoilsPvc PipesPvc Pipe FittingsUpvc PipesUpvc Ball ValvePipe Elbows