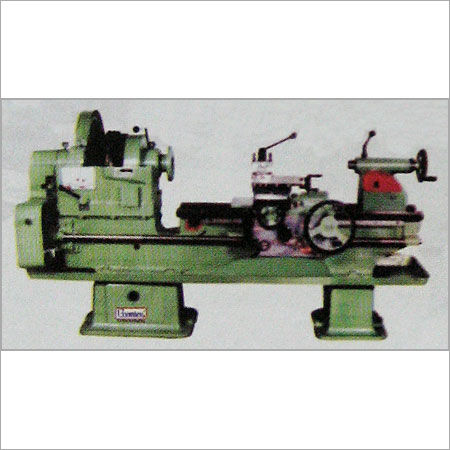

Extra Heavy Duty Lathe Machine By Simplex Engineering Works

Lathe Machine

We

are a leading manufacturer of best quality Extra heavy duty lathe

machines, which are valued amidst our ...View Product Details

Product Overview

Key Features

Lathe Machine

We

are a leading manufacturer of best quality Extra heavy duty lathe

machines, which are valued amidst our clients for their high efficiency

and reliable functionality in our extra heavy duty lathe machines. The

materials used in manufacturing Extra heavy duty lathe machines are of

premium quality and impart them long lasting features. These Extra

heavy duty lathe machines are capable of working under severe

conditions with less maintenance cost. These extra heavy duty lathe

machine are offered by us in standard as well as customized dimensions,

finishes and other specifications.

Special

Features

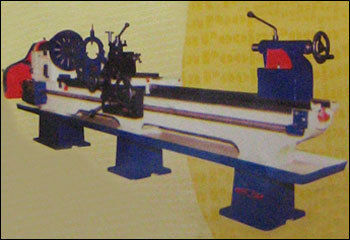

Lathe

Machine : It's deep wide and internally reinforced by a new and latest

system of webs which enable it to take up heavy thrust of tools without

vibration and is made of close grained cast iron, mixed with salts to

attain requisite hardness & to prevent any possibility of

distortion either horizontally or vertically. It is V-Type and

accurately hand scrapped. A removable gap piece is fixed with 2

location pins for perfect alignment. The bed consists of three vees.

The

Leadscrew : is inch calibrated and is made of high resistant alloy

steel,It has a large diameter and its thread has a very high degree of

precision in Lathe machine

Head stock : The flat seat of head

stock over bed is perfectly matched by precision hand scrapping. It s

spindle is made from high carbon steel which rotates on two cylindrical

precision split type gun metal bushes of Grade-I composition both at

the front and at the back for smooth running and perfect balancing and

thrust of the spindle is taken by heavy duty thrust bearings. The Lathe

machine are also made by fitting Taper Roller Bearings in the head

stock.

Tail Stock : It is strong, rigid and provided with

set-over motion for taper turning. Its quill is fairly thick and

properly graduated.

The Apron : The Apron is of double wall

design with automatic interlock to prevent simultaneous engagement of

feed shaft and lead screw in Lathe machine. All gears and bearings

including worm have suitable oiling arrangement.

Carriage : It

is of robust design and provided with long carefully scrapped sliding

surfaces. The swiveling compound slide is accurately indexed for taper

turning and has a four-way steel turret tool post.Standard Equipment :

Face plate, Steady rest, Follow rest. Thread dial gauge, 2 M.T. Centre.

Over head counter shafts (with belt driven lathes only ) and a set of

22 change wheels.

Technical

Specification

MODEL

SEL 16mm

SEL 18mm

SEL 20mm

SEL 24mm

SEL 26mm

SEL 30mm

SEL 36mm

SEL 40mm

SEL 48mm

SEL 60mm

Length of Bed

4900

5500

6100

7300

7900

9150

10970

12200

14600

18300

Width of Bed

650

700

750

800

900

1000

1050

1150

1250

1500

Height of Center

600

650

700

750

850

950

1000

1100

1150

1350

Distance Between

Center

2850

3450

4050

5150

5750

6800

8500

9600

11700

15000

Spindle Hollow

103

103

103

103

103

103

127

150

150

150

Swing over Saddle

(Dia)

950

1050

1100

1150

1400

1600

1650

1850

1950

2350

Swing Over Bed (Dia)

1200

1300

1400

1500

1700

1900

2000

2200

2300

2700

Swing Over Gap (Dia)

1700

1800

1900

2000

2200

2400

2500

2700

2800

3250

No. of Spindle

Speeds

6

6

6

6

6

6

6

6

6

6

Lead Screw Dia

60

60

60

60

60

75

80

85

85

85

Lead Screw Pitch

T.P.I.

2

2

2

2

2

2

2

2

2

2

H.P. Recommended

7.5

10

10

15

20

20

25

30

30

20

Company Details

Business Type

Exporter, Importer, Manufacturer, Distributor, Supplier, Trading Company

Employee Count

20

Establishment

1980

GST NO

03AAVPK7405Q2Z1

Seller Details

Simplex Engineering works

GST

03AAVPK7405Q2Z1

GM

Mr. Sahil

Address

G.T. Road, Asr Bye Pass Chowk, Batala, Punjab, 143505, India

heavy duty lathe machine in BatalaReport incorrect details

Related Products

Mild Steel Material Lathe Machines For Industrial Applications

Price - 250000 INR (Approx.)

MOQ - 1 Piece/Pieces

SHIVALIK CAST AND FORGE

Batala, Punjab

Automatic Heavy Duty Cone Pulley Belt Driven Lathe Machine

MOQ - 1 Unit/Units

OM INTERNATIONAL MACHINE TOOLS

Batala, Punjab

Semi Automatic Heavy Duty Lathe Machine

Price - 200000 INR (Approx.)

MOQ - 10 Unit/Units

ARVIND ENTERPRISES

Batala, Punjab

450 Mm Planner Type Heavy Duty Lathe Machine, Maximum Swing in Gap: 1250 mm

R. P. ENGINEERING COMPANY

Batala, Punjab

White And Blue 10 Feet Big Bore Heavy Duty Lathe Machine

Price - 290000 INR (Approx.)

MOQ - 1 Unit/Units

O.P.S Udyog

Batala, Punjab

More Products From This Seller

Explore Related Categories

- Tradeindia

- Lathe Machine

- Heavy Duty Lathe Machine

- Extra Heavy Duty Lathe Machine In Asr Bye Pass Chowk

Recommended Products

Popular Products

Human HairForklift TrucksServo Voltage StabilizerBasmati RiceBackhoe LoaderCarry Bag Making MachineDrum LifterElectric StackerScissor LiftsIndustrial Vibrating ScreenRotameterFlowmeterRotary Air CompressorIndustrial Eto SterilizerRice Packaging MachinesShredding MachineHammer MillAutomatic Labelling MachineDiesel ForkliftAerial Work PlatformStorage Rack SystemEpoxy ResinMild Steel BarStainless Steel SheetsStainless Steel StripsBag Filling MachinesAsphalt PlantsSlat ConveyorOintment PlantPlanetary MixersLadies KurtisLed LightsCctv CameraBall ValveAnti Cancer MedicineAir CompressorIncense SticksSolar LightsGoods LiftsVitrified TilesStainless Steel CoilsPvc PipesPvc Pipe FittingsUpvc PipesUpvc Ball ValvePipe Elbows