Product Overview

Key Features

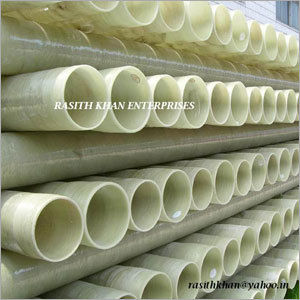

Our team of proficient has enabled us to manufacture, export and supply a huge assortment of optimum quality FRP Pipe. By our experts, this pipe is manufactured with the utilization of cutting-edge techniques at our well-equipped manufacturing setup. This pipe is used in construction, industrial, household as well as commecrial applications. Known for its outstanding features, the provided pipe is highly acclaimed by the clients all across the country. In addition, clients can avail this FRP Pipe at highly competitive rates from us. Features: Rust proof nature Accurate dimensions Easy installation High strength Nominal Diameter ND SONAL pipe is manufactured in the following diameters. Special application diameters are available upon request, as specified by, ASTM D3754, D3262& D3517 DN 100 500 1300 150 600 1400 200 700 1500 250 800 1600 300 900 1800 350 1000 2000 400 1200 2400 Pipe Length SONAL GRP Pipe are manufactured in a standard 6 & 12 meter length. Special lengths are available upon request. Typical mechanical properties of the structural wall of SONAL pipe Property Test Method Value Density ASTM D 2584 1580-1850 kg/m3 Hoop Tensile Strength Bs 5480 : 1990 @ 230 350-490 N/mm Axial Tensile Strength BS 5480;1990@ 230 148-169 N/mm Hoop Tensile Strength From pressure tests @ 230 28000-30000 N/mm Compressive Strength ASTM D 695 208-364 N/mm Compressive Modulus 10000 N/m STIFFNESS CLASSESWhen pipes are used for underground applications, the load application on the pipe due to the depth of cover backfill and traffic load etc, could cause the deflection of the pipe, ultimately results pipe failure. So to avoid these failure, stiffness tests are performed as per ASTM D2412. Stiffness class Minimum Stis Minimum Pipe Stiffness (PS) (El/Di) Pa F/Y=El(0.149p) kpa SN 2500 2500 124.0 SN 5000 5000 248.0 SN 10000 10000 496.0 A specific stiffness class corresponds the specific cover of back fill, so stiffness class should be choosed carefully according to the required cover backfill, to avoid pipe failure. Stiffness class Minimum Cover in m (related with soil nature) 2500 8 5000 12 10000 16 Stiffness class selection for a particular project is depending on customers requirement; the engineer in charge can advise it keeping in view the site requirements, like traffic load and native soil. Our technical division is also available for recommendations;Pressure classesSONAL pipe are supplied in the following pressure classes Pressure Pressure Classes Rating PN Bar Gravity 0.5 6 6 10 10 16 16 Higher rating pipe line are available on demand; consult our technical department for details.Joint angular deflectionThe joint is extensively and qualified in accordance with ASTM D4161.Maximum angular deflection at each joint, considering both combined at each and horizontal, measured as the change in adjacent given the table 1.When the joints intended for use of pressure greater 17 bar, many have lower allowable angular deflection than given table bellow.Flow velocityMaximum recommended flow velocity is 3.0. Velocities of up to 4m/sec can be used if the water is clean and contain no abrasive material.Chemical resistanceGRP pipes are corrosion resistant to numerous everyday products, alternatively pipes and associated products can be supplied with a formulation from the worlds resin manufactures to suit your special application. Our technical department will assist to meet your requirements.Thermal coefficient of expansionThe thermal coefficient of axial expansion and contraction for SONAL pie is 24 to 30*10-6 cm/cmo C.SONAL pipe is made of glass fiber reinforced plastic. It is produced by filament winding machines, by reproducible processes. All these pipe are provided with resin rich interior layers, providing very smooth inner surface, qualifying AWWA & ASTM standards. This smooth interior surfaces results in very low fluid resistance.For hydraulic analysis of the very piping system, pipe toughness is the concern.This roughness is being used in various forms in various updating of hydraulic analysis. Head loss:To assist the designer in estimating the head loss associated by using SONAL pipe. Figure 1-3 and 1-4 are provided, when using the chart to estimate the head loss for pipes not specifically noted on the chart. (Due to slight inside diameter variance), he error will be less than 7% for flow velocities between 1 & 3 m/sec, contact us for more details.Abrasion resistanceAbrasion resistance can be related to the effects that sand or other similar material may have on the interior surface of the pipe. While there is no widely standardized testing procedure or ranking method, however certain test reports are available. Our technical department has such references and these are available on demand.General there are two types of joints:Restrained (Tensile resistant)Flanged jointButt and strap jointRubber seal locked jointAdhesive jointNon-restrainedBell and spigotDouble bell coupling Usually following system of jointing is usedFLANGED JOINTTo enable connections with steel and to allow for easy assembling and disassembling of process lines, extralite pipes can be supplied with flanges, drilled in accordance with ANSI, BS, DIN or other specifications. Special requirements can be upon request.BUTT AND STRAP JOINTIn general, these joints will only be used for diameters over 400mm. The preparation for this rigid joint requires good craftsmanship.DOUBLE BELL COUPLINGShort pipes are joined using double bell coupling. The sealing of the joint is achieved by the compression of two elastomeric rubber gaskets when the joint is assembled.BELL AND SPIGOT JOINTThe socket end of this joint is an integral filament wound part of the pipe. The spigot end is a machined part n which O-ring seal is positioned. The flexible joint allows for axial movement of the spigot in the socket and some permissible angular deflection.RUBBER SEAL LOCK JOINTThis type of joint consists of an integral filament wound socket end and a machined spigot end. The O-ring seal is positioned on the spigot end. The locking device is inserted through an opening in the socket end. If fits in a circumferential groove on the inner side of the socked end and rests against a shoulder on the spigot end. Extralite rubber seal lock joint allows for some axial movement as well as a certain angular deflection.ADHESIVE JOINTPipes are produced with integral socket and spigot ends. Ends are slightly tapered. The inside of the socket matches with the outside of the machined spigot. The two component of the adhesive, namely, epoxy resin and hardner are supplied in appropriately seized cans in correct mixing ratio. 10,000 STIS PIPE B Class (BAR PIPE) C Class (9 BAR PIPE) D Class (12 BAR PIPE) 80 3.5 1.651797 3.5 1.651797 3.5 1.651797 100 3.5 2.047437 3.5 2.047437 3.5 2.047437 150 4.7 4.109513 4.7 4.109513 4.7 4.109513 200 5.3 6.149885 5.3 6.149885 5.3 6.149885 250 6.5 9.423297 6.5 9.423297 6.5 9.423297 300 7.6 13.21302 7.6 13.21302 7.6 13.21302 350 6.81 13.73366 6.91 13.93923 7.16 14.45367 400 7.36 16.94565 7.45 17.15666 7.84 18.07208 450 8.18 21.1832 8.26 21.39411 8.78 22.76676 500 9.02 25.95037 8.94 25.71617 9.78 28.17888 600 10.73 37.03831 10.85 37.45989 11.71 40.48598 700 12.34 49.68264 12.49 50.29715 13.68 55.18128 800 13.95 64.17621 14.14 65.06548 15.53 71.5836 900 15.61 80.78218 15.78 81.6771 17.32 89.79888 1000 17.23 99.06189 17.45 100.3484 19.25 110.8954 1100 18.86 119.2668 19.08 120.6818 21.15 134.022 1200 20.49 141.3443 20.74 143.0982 22.95 158.633 1300 22.08 164.9905 22.42 167.5742 24.82 185.8492 1400 23.74 191.0353 24.06 193.6538 26.65 214.8903 Fitting and pipeline assecoriesSONAL is producing stub mitred fabricated fittings using the same materials that are used to produce SONAL GRP Pipe. One of the benefits of SONAL pipe is the ability is the ability to fabricate a wide assortment of fittings, standard as well as non-standard. GRP molded fittings are fabricated for certain specific requirement. The following tables shows the standard dimensions of standard fittings with different ends configuration.

Company Details

Business Type

Manufacturer, Distributor, Supplier, Trading Company

Employee Count

100

Establishment

1998

Working Days

Monday To Sunday

GST NO

27AEQPM2032Q1ZY

Seller Details

SONAL ENGG PLASTIC FABRICATOR

GST

27AEQPM2032Q1ZY

Director

Mr Abhishek Anil Mhatre

Member Since

1 Year

Address

67th Sonal House, Bhaimala, Post-Kamarle, Midc Road, Dist-Raigad, Raigad, Maharashtra, 402207, India

Report incorrect details

Related Products

More Products From This Seller

Explore Related Categories

- Tradeindia

- Pipes & Pipe Fittings

- Frp Pipes

- Frp Pipes In Dist-raigad

Popular Products

Human HairForklift TrucksServo Voltage StabilizerBasmati RiceBackhoe LoaderCarry Bag Making MachineDrum LifterElectric StackerScissor LiftsIndustrial Vibrating ScreenRotameterFlowmeterRotary Air CompressorIndustrial Eto SterilizerRice Packaging MachinesShredding MachineHammer MillAutomatic Labelling MachineDiesel ForkliftAerial Work PlatformStorage Rack SystemEpoxy ResinMild Steel BarStainless Steel SheetsStainless Steel StripsBag Filling MachinesAsphalt PlantsSlat ConveyorOintment PlantPlanetary MixersLadies KurtisLed LightsCctv CameraBall ValveAnti Cancer MedicineAir CompressorIncense SticksSolar LightsGoods LiftsVitrified TilesStainless Steel CoilsPvc PipesPvc Pipe FittingsUpvc PipesUpvc Ball ValvePipe Elbows