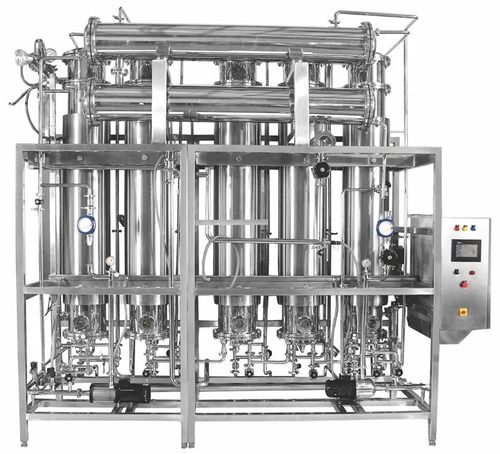

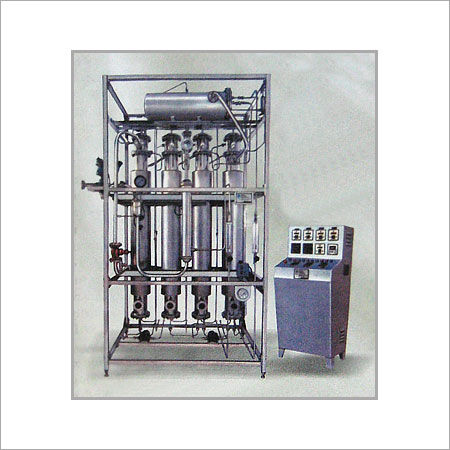

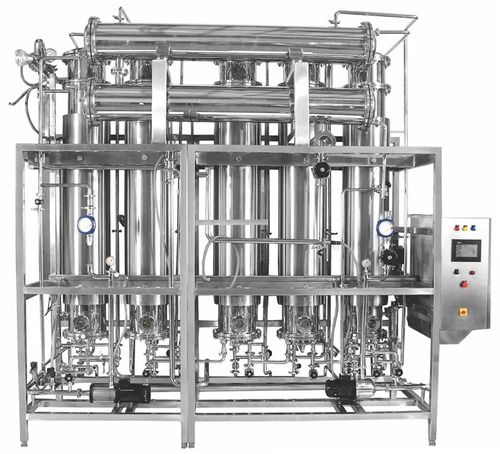

Multi Column Distillation Plant By Ravi-kiran Industries

Get LatestPrice

Get Best Deals

Multi Column Distillation Plant DescriptionMulti column distilled water still is designed to produce sterile, pyrogen free distilled water conforming...View Product Details

Product Overview

Key Features

Multi Column Distillation Plant DescriptionMulti column distilled water still is designed to produce sterile, pyrogen free distilled water conforming to I.P. / B.P. specifications. The still works on interstage heat exchange principle whereby the distillate is produced at a fraction of the cost as compared to single column stills. All contact parts are made out of AISI 316 quality and mirror polished. OperationMulti column distilled water still works on interstage heat exchange principle. The pre-heated feed water is fed to the first column where it is heated by means of steam from the boiler. Due to heat exchange, surface evaporation of the feed water takes place whereby a part of the feed water is converted into steam. In the process the steam itself condenses back to water. The steam with high velocity and under pressure passes through a specially designed spiral which creates a unique centrifugal force which removes impurities such as pyrogens and exdotoxins which are blown out of the system. Condensing vapor from the previous stage is used as heating vapour for the next stage. The process is repeated through the last column, each column working at a lower pressure and temperature than the previous one. Due to the pressure difference between the columns, the energy supplied to the first column is repeatedly re-used in the system. Only the first column is heated using an external source of energy and only the vapour from the last column is condensed with external cooling water. Thus upto 70% energy is saved.Salient Features100% pyrogen free distilled water conforming to I.P. / B.P. specifications.High initial cost but low operational cost.Saving upto 70% of energy as compared to single column stills.Low on maintenance as no moving parts except feed pump.The unit can be operated at a higher steam pressure to get upto 50% higher output.Automatic dumping of sub-standard distillate.Low level controls for feed water.Conductivity meter to continuously monitor the quality of final distillate. Scope of SupplyS.S. 316 quality multi-stage pump for Feed water, max. pressure of 10kg/cm2S.S. 304 Centrifugal pump for cooling water.S.S. 316 quality Surge tank with level switch to maintain the level of feed water.S.S. 316 quality pneumatic three way valve for automatic dumping of sub-standard distillate.S.S. 304 stand instead of mild steel stand.Fully automatic operation, controlled through a specially designed S.S. electronic panel board with self regulating sensors to keep each of the operating parameters within the pre-set limits, hence no skilled labour required to operate the plant.Magnetic level switch in the first column to maintain the level of feed water in the column.Pressure switch to monitor the pressure of feed water.Pressure gauges, safety valve, rotameters etc. *No extra cost for the surge tank and S.S. stand. Optional Accessories If RequiredS.S. Housing filter for filtration of feed water.Diaphragm steam pressure reducing valve.PLC based control panel. Technical Specifications Material All contact parts are made out of AISI 316 quality. All tubing is seamless Sealant P.T.F.E. Distillate Quality As per I.P. / B.P. specifications Distillate Temp. Approx. 95C Feed Water Quality De-Ionized mineral water with a max. conductivity of 5 micro Siemens / cm2 Feed Water Pressure 1kg/cm2 higher than the boiler steam pressure Cooling Water Normal tap water, hardness less than 90 PPM of CACO Steam Saturated dry, free from oil, vapours and other impurities Electricals 440 V, 3Phase, 50Hz Max. Load: 5k.w. approx. Model Distilled Water Output (ltr./Hr.) Steam consumption (kg./Hr.) D.M. Water consumption (Feed water ltr./Hr.) Cooling water consumption (ltr./Hr.) Dimensions in mm Ltrs/Columns Steam Pressure (kg/cm2) Steam Pressure (kg/cm2) Steam Pressure (kg/cm2) Steam Pressure (kg/cm2) Length. Width Ht. 3 4 5 6 3 4 5 6 3 4 5 6 3 4 5 6 150/4 150 180 200 230 49 60 70 80 171 206 240 265 130 170 200 235 1880 870 3030 300/4 300 350 400 450 96 121 145 166 346 415 481 530 300 380 400 460 1980 975 3050 500/5 500 600 700 750 130 160 192 220 575 692 795 890 250 325 395 440 2630 975 3960 1000/5 1000 1200 1400 1550 240 300 355 455 1150 1390 1600 1955 900 1000 1100 1250 3025 2500 3975

Company Details

RAVI-KIRAN INDUSTRIES, Established in 1985 at Mumbai in Maharashtra, is a leading Exporter,Manufacturer,Supplier of Pharmaceutical Machinery in India. RAVI-KIRAN INDUSTRIES is one of Trade India's verified and trusted sellers of listed products. With extensive experience in supplying and trading Multi Column Distillation Plant, RAVI-KIRAN INDUSTRIES has made a reputed name for itself in the market with high-quality Automatic Tube Filling Machine, Capsule Filling, Capsule Loader, etc.

Focusing on a customer-centric approach, RAVI-KIRAN INDUSTRIES has a pan-India presence and caters to a huge consumer base throughout the country. Buy Pharmaceutical Machinery in bulk from RAVI-KIRAN INDUSTRIES at Trade India quality-assured products.

Focusing on a customer-centric approach, RAVI-KIRAN INDUSTRIES has a pan-India presence and caters to a huge consumer base throughout the country. Buy Pharmaceutical Machinery in bulk from RAVI-KIRAN INDUSTRIES at Trade India quality-assured products.

Business Type

Exporter, Manufacturer, Supplier

Establishment

1985

Working Days

Monday To Sunday

Seller Details

R

RAVI-KIRAN INDUSTRIES

Director

Mr. Samir Sampat

Address

No. 213, Mittal Estate No. 2, Marol Naka, Andheri East, Mumbai, Maharashtra, 400059, India

multi column distillation plant in MumbaiReport incorrect details

Related Products

Multi Column Distillation Plants Capacity: 50-10000 Liter (L)

Price - 10,00,000 - 100,00,000 INR INR (Approx.)

MOQ - 1 Plant/Plants

STERINOX SYSTEMS

Mumbai, Maharashtra

More Products From This Seller

Explore Related Categories

- Tradeindia

- Water Treatment Plants

- Multi Column Distillation Plant

- Multi Column Distillation Plant In Marol Naka-andheri (E)

Recommended Products

Popular Products

Human HairForklift TrucksServo Voltage StabilizerBasmati RiceBackhoe LoaderCarry Bag Making MachineDrum LifterElectric StackerScissor LiftsIndustrial Vibrating ScreenRotameterFlowmeterRotary Air CompressorIndustrial Eto SterilizerRice Packaging MachinesShredding MachineHammer MillAutomatic Labelling MachineDiesel ForkliftAerial Work PlatformStorage Rack SystemEpoxy ResinMild Steel BarStainless Steel SheetsStainless Steel StripsBag Filling MachinesAsphalt PlantsSlat ConveyorOintment PlantPlanetary MixersLadies KurtisLed LightsCctv CameraBall ValveAnti Cancer MedicineAir CompressorIncense SticksSolar LightsGoods LiftsVitrified TilesStainless Steel CoilsPvc PipesPvc Pipe FittingsUpvc PipesUpvc Ball ValvePipe Elbows