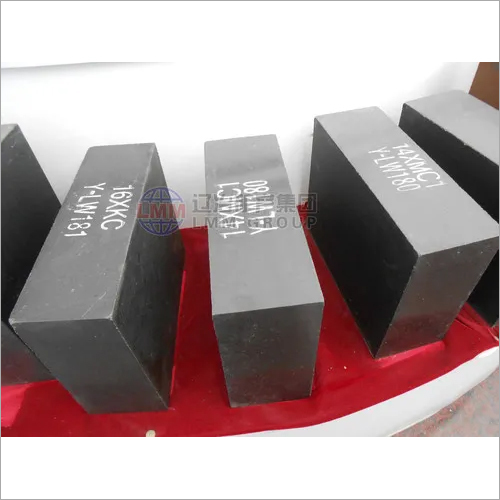

Refractory Fused Direct-bonded Magnesia Chrome Brick

Price Trend: 450.00 - 1200.00 USD

Get LatestPrice

| FOB Port | tianjin |

| Delivery Time | 25 Days |

| Sample Available | Yes |

| Sample Policy | Free samples are available |

Product Overview

Key Features

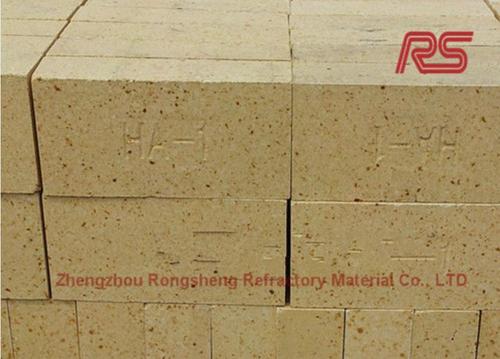

We are Making, Exporting and Supplying best quality Refractory Fused Direct-Bonded Magnesia Chrome Brick in Zhengzhou, Henan, China. Magnesia-chrome bricks are refractory products containing magnesium oxide (MgO) and chromium oxide (Cr2O3) as the main components, and periclase and spinel are the main mineral components. This type of brick has high refractoriness, high temperature strength, strong resistance to alkaline slag, excellent thermal stability, and certain adaptability to acidic slag.

Magnesia-chrome bricks The main raw materials for the manufacture of magnesia chrome bricks are sintered magnesia and chromite. The purity of the magnesia raw material should be as high as possible. The requirements for the chemical composition of the chromite ore are: Cr2O3: 30-45%, CaO: a 1.0-1.5%.

Magnesia chrome brick a c Instructions for use

Magnesia-chrome bricks are mainly used in metallurgical industries, such as the construction of open hearth furnace roofs, electric furnace tops, furnace refining furnaces, and various non-ferrous metal smelting furnaces. The high temperature part of the ultra high power electric furnace wall is made of fused cast magnesia chrome brick. The high erosive area of a a the refining furnace outside the furnace is made of magnesia chrome brick made of synthetic material. The high erosive area of a a nonferrous metal flash smelting furnace is made by melting cast magnesia chrome brick and synthetic material. Magnesia chrome bricks. In addition, magnesia-chrome bricks are also used in cement rotary kiln firing zones and glass kiln regenerators.

Magnesia chrome brick a c production process

Magnesia-chrome bricksThe production process of firing magnesia-chrome bricks is similar to that of magnesia bricks. In order to eliminate the brick during the firing process due to MgO and Cr2O3, Al2O3 or directly combined with magnesia chrome bricks

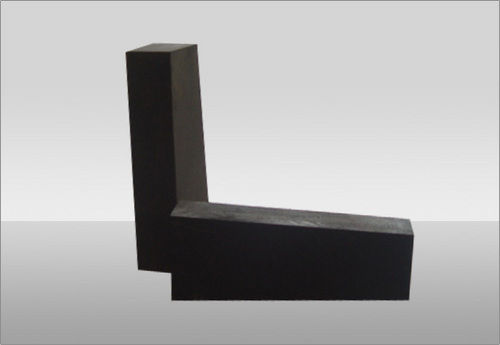

The loosening effect caused by the expansion of iron oxides to form spinel can also be made into a magnesia chrome brick using a synthetic co-sintered material. In addition, there are non-calcined magnesia chrome bricks, for example, non-calcined magnesia chrome bricks combined with an inorganic magnesium salt solution. The non-burned magnesia chrome brick has a simple production process, low cost and good thermal stability, but the high temperature strength is far less than that of the fired brick. In the late 1950s, a so-called "direct combination" magnesia chrome brick was developed. The brick is characterized by pure raw materials, high firing temperature, direct combination of high temperature phases such as periclite and spinel, and low-melting phase such as silicate is island-like distribution, thus significantly increasing the high temperature of the brick. Strength and slag resistance.

Magnesia-chrome bricksThe method of preparing the fine powder prepared by calcining the calcined billet with chrome ore-magnesia sand and the coarse particles of magnesia is an effective measure for eliminating the loose effect. Compared with ordinary magnesia chrome bricks, the magnesia chrome bricks produced by this method have low porosity, high compressive strength, load softening temperature and flexural strength. Magnesia-chrome bricks made of chrome-magnesia powder compacts and high-temperature calcined synthetic magnesia-chrome sands are better than other magnesia-chrome bricks in slag resistance and high temperature strength.

Magnesia-chrome bricks In addition, there is a molten cast magnesia chrome brick which is directly cast by using an electric orphan furnace molten magnesium chrome material, and a molten granule produced by the fused magnesia chrome material according to the brick making process and a magnesia chrome brick.

Magnesia-chrome bricks The main raw materials for the manufacture of magnesia chrome bricks are sintered magnesia and chromite. The purity of the magnesia raw material should be as high as possible. The requirements for the chemical composition of the chromite ore are: Cr2O3: 30-45%, CaO: a 1.0-1.5%.

Magnesia chrome brick a c Instructions for use

Magnesia-chrome bricks are mainly used in metallurgical industries, such as the construction of open hearth furnace roofs, electric furnace tops, furnace refining furnaces, and various non-ferrous metal smelting furnaces. The high temperature part of the ultra high power electric furnace wall is made of fused cast magnesia chrome brick. The high erosive area of a a the refining furnace outside the furnace is made of magnesia chrome brick made of synthetic material. The high erosive area of a a nonferrous metal flash smelting furnace is made by melting cast magnesia chrome brick and synthetic material. Magnesia chrome bricks. In addition, magnesia-chrome bricks are also used in cement rotary kiln firing zones and glass kiln regenerators.

Magnesia chrome brick a c production process

Magnesia-chrome bricksThe production process of firing magnesia-chrome bricks is similar to that of magnesia bricks. In order to eliminate the brick during the firing process due to MgO and Cr2O3, Al2O3 or directly combined with magnesia chrome bricks

The loosening effect caused by the expansion of iron oxides to form spinel can also be made into a magnesia chrome brick using a synthetic co-sintered material. In addition, there are non-calcined magnesia chrome bricks, for example, non-calcined magnesia chrome bricks combined with an inorganic magnesium salt solution. The non-burned magnesia chrome brick has a simple production process, low cost and good thermal stability, but the high temperature strength is far less than that of the fired brick. In the late 1950s, a so-called "direct combination" magnesia chrome brick was developed. The brick is characterized by pure raw materials, high firing temperature, direct combination of high temperature phases such as periclite and spinel, and low-melting phase such as silicate is island-like distribution, thus significantly increasing the high temperature of the brick. Strength and slag resistance.

Magnesia-chrome bricksThe method of preparing the fine powder prepared by calcining the calcined billet with chrome ore-magnesia sand and the coarse particles of magnesia is an effective measure for eliminating the loose effect. Compared with ordinary magnesia chrome bricks, the magnesia chrome bricks produced by this method have low porosity, high compressive strength, load softening temperature and flexural strength. Magnesia-chrome bricks made of chrome-magnesia powder compacts and high-temperature calcined synthetic magnesia-chrome sands are better than other magnesia-chrome bricks in slag resistance and high temperature strength.

Magnesia-chrome bricks In addition, there is a molten cast magnesia chrome brick which is directly cast by using an electric orphan furnace molten magnesium chrome material, and a molten granule produced by the fused magnesia chrome material according to the brick making process and a magnesia chrome brick.

Explore in hindi - रिफ्रैक्टरी फ्यूज्ड डायरेक्ट-बॉन्डेड मैग्नेशिया क्रोम ब्रिक

Company Details

Business Type

Exporter, Manufacturer, Supplier

Employee Count

300

Establishment

2002

Working Days

Monday To Sunday

Seller Details

H

Henan Hongtai Kiln Refractory Co., Ltd.

Rating

5

sales manager

Ms Cindy zhang

Address

No. 4 Group, Chuling Village, Chaohua Town, Xinmi, Zhengzhou, Henan, 452370, China

refractory bricks in ZhengzhouReport incorrect details

Related Products

Power Press For Refractory Brick Grade: Commercial Use

Zhengzhou Haloong Machinery Manufacturing Co., Ltd.

Zhengzhou, Henan

Andalusite Refractory Brick For Flue-Wall Compressive Strength: A Y60 Megapascals (Mpa )

MOQ - 30 Ton/Tons

Jundao (Henan) New Refractory Co.,Ltd

Zhengzhou, Henan

More Products From This Seller

Explore Related Categories

- Tradeindia

- Bricks

- Refractory Bricks

- Refractory Fused Direct-bonded Magnesia Chrome Brick In Xinmi

Recommended Products

Popular Products

Human HairForklift TrucksServo Voltage StabilizerBasmati RiceBackhoe LoaderCarry Bag Making MachineDrum LifterElectric StackerScissor LiftsIndustrial Vibrating ScreenRotameterFlowmeterRotary Air CompressorIndustrial Eto SterilizerRice Packaging MachinesShredding MachineHammer MillAutomatic Labelling MachineDiesel ForkliftAerial Work PlatformStorage Rack SystemEpoxy ResinMild Steel BarStainless Steel SheetsStainless Steel StripsBag Filling MachinesAsphalt PlantsSlat ConveyorOintment PlantPlanetary MixersLadies KurtisLed LightsCctv CameraBall ValveAnti Cancer MedicineAir CompressorIncense SticksSolar LightsGoods LiftsVitrified TilesStainless Steel CoilsPvc PipesPvc Pipe FittingsUpvc PipesUpvc Ball ValvePipe Elbows