Sonic Cleaning Systems

Get LatestPrice

Get Best Deals

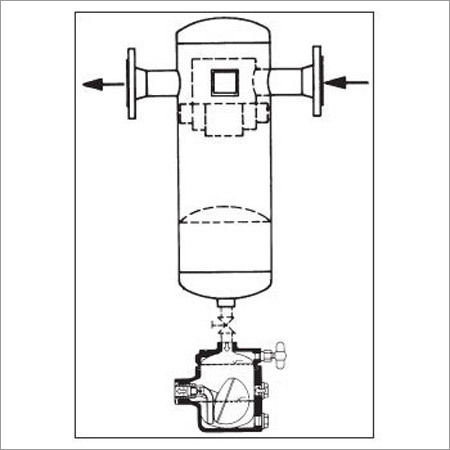

SONIC CLEANING SYSTEM The method of Sonic Cleaning is in fact more useful to Keep Clean than to clean a dust coated surface. If the la...View Product Details

Product Overview

Key Features

SONIC CLEANING SYSTEM The method of Sonic Cleaning is in fact more useful to Keep Clean than to clean a dust coated surface. If the layer has already been allowed to grew too much the physical properties of the deposit can be too severe, the outer surface hardened or sintered and may cause strong adhesion to the tube. But if we permit the cleaning work periodically with short intervals, the results will be surprisingly good. High Energy low frequency Sonic Power Systems are engineered and designed for corrosive and high temp. environments. Their Fundamental Frequencies at 147 decibels (db) are in the optimum range to fluidizing soot and dust clinging to tubes and surfaces. BEP Acoustic Horn is powered by compressed air and is controlled electrically by means of a solenoid valve. A high level of operational reliability is ensured by the fact that the diaphragm is the only moving part in the unit. A complete installation for Sonic cleaning consists of a number of sonic horns and an automatic control unit, which is programmed for both the duration of the sound (i.e. 15 to 30 seconds) and the length of the interval between Isonations. Interval time must be determined by experience. The Sonic Horns in water tube boilers are mounted in wall openings, with the horns between the heating surfaces, in much the same manner as a soot blower. In fire tube boilers the horns should be placed relatively close to the tube openings, but not necessarily directed against them. There have been a large number of different applications already, characterized by reduced maintenance cost, increased boiler efficiency, reduced break down frequency, reduced tube changes etc. The particle emission from the stack has been influenced in a favorably way. The well known trouble with smoke flakes, leading to fall down close to the plant. In many cases the added sound method means the benefit of prolonged interval between the mechanical cleaning procedures thus giving an essentially improved economy and availability.SONIC CLEANING APPLICATIONS: * Soot blowing of boilers, economizers and air heaters. * To reduce pressure drop in bag house and increasing bag life. * Fluidizing dust in bins and hoppers. * Cleaning precipitator distribution plates, collecting plates and wires. * Eliminating build up on fans. ADVANTAGES OF SONIC CLEANING : EFFECTIVE CLEANING: Sonic Cleaning achieves a uniform cleaning effect. The sound waves flow around tubes corners and keeps even inaccessible places clean. CONTINUOUS CLEANING: Sonic Cleaning due to its comparatively high frequency of operation can considered as a Continuous cleaning method which prevents dust/soot build up. Periodic mechanical cleaning on the other hand allows dust/soot build up before cleaning is undertaken. In steam generators continuous cleaning means high heat transfer efficiency and lower flue gas temperature whereas in applications like dust collectors it means reduced pressure drop hence reduced power consumption. In all cases the output capacity of the equipment is significantly improved as a result of sonic cleaning. INCREASED EQUIPMENT AVAILABILITY: Sonic Cleaning eliminates or in some cases dramatically reduces equipment down time required for mechanical cleaning. LOWER OPERATING COSTS : Operating cost of a sonic soot blower is very low as compared to a steam blower, which may consume about 2% of the steam generated. INCREASED SERVICE LIFE OF EQUIPMENT : Mechanical cleaning systems cause considerable wear on the cleaned surfaces reducing their service life. Sonic cleaning imparts energy only to the particular matter causing them to dislodge from the surface. LOW MAINTENANCE : Sonic horns due to their simple construction have minor service requirements.

Company Details

Business Type

Manufacturer, Supplier

Employee Count

25

Establishment

2011

Seller Details

B

BEP ENGINEERING PVT. LTD.

Director

Mr. S. P. Bafna

Address

G- 201, Kumar Padmaja, Opp. Mahesh Vidyalaya, Kothrud, Pune, Maharashtra, 411038, India

Engineering Goods & Equipment in PuneReport incorrect details

Related Products

Silver Aluminium Bell Housing

Price - 500 INR (Approx.)

MOQ - 10 , Piece/Pieces

JACKTECH HYDRAULICS

Ahmedabad, Gujarat

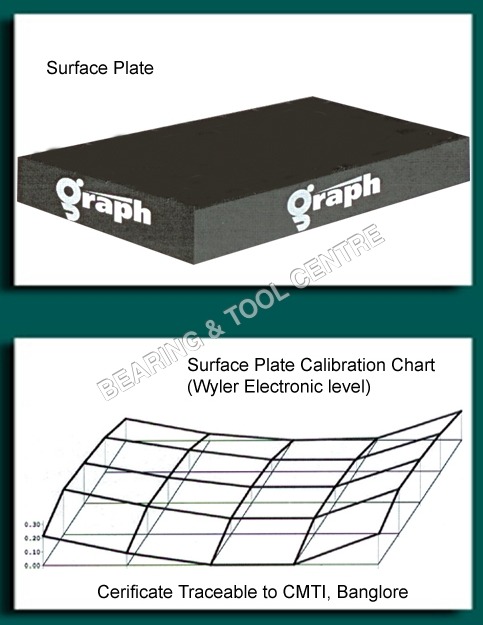

Granite Surface Plate Application: For Laboratory Use

Price - 2250 INR (Approx.)

MOQ - 1 Unit/Units

BEARING & TOOL CENTRE

Ahmedabad, Gujarat

More Products From This Seller

- Tradeindia

- Engineering Goods & Equipment

- Sonic Cleaning Systems In Kothrud

Recommended Products

Popular Products

Human HairForklift TrucksServo Voltage StabilizerBasmati RiceBackhoe LoaderCarry Bag Making MachineDrum LifterElectric StackerScissor LiftsIndustrial Vibrating ScreenRotameterFlowmeterRotary Air CompressorIndustrial Eto SterilizerRice Packaging MachinesShredding MachineHammer MillAutomatic Labelling MachineDiesel ForkliftAerial Work PlatformStorage Rack SystemEpoxy ResinMild Steel BarStainless Steel SheetsStainless Steel StripsBag Filling MachinesAsphalt PlantsSlat ConveyorOintment PlantPlanetary MixersLadies KurtisLed LightsCctv CameraBall ValveAnti Cancer MedicineAir CompressorIncense SticksSolar LightsGoods LiftsVitrified TilesStainless Steel CoilsPvc PipesPvc Pipe FittingsUpvc PipesUpvc Ball ValvePipe Elbows