Thermal Chip Dryer

Get LatestPrice

| Sample Available | Yes |

| Sample Policy | Contact us for information regarding our sample policy |

| Main Export Market(s) | Asia |

| Main Domestic Market | All India |

Product Overview

Key Features

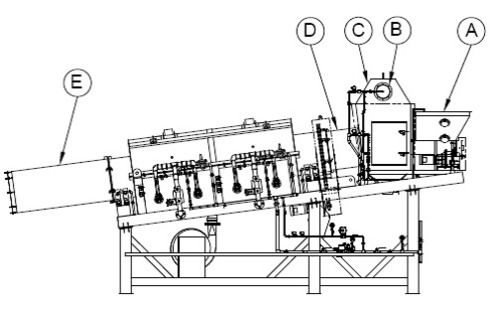

Being one of the trusted organizations in the market, we are reckoned in exporting, manufacturing and supplying an extensive array of Thermal Chip Dryer for our esteemed clients in Vadodara, Gujarat, India. Chips from machining operations are fed into the screw feeder hopper (A). The screw feeder feeds the chips into the rotary hearth (D) at a constant rate. In the rotary hearth, the chips are typically heated to a set point temperature between 800 and 900A F to vaporize the water and oil. Products inside the rotary hearth (D) are indirectly heated. Natural gas fired burners/furnace oil burner to heat the rotary hearth from the outside. These burners are fired into a cavity between the outside of the rotary hearth and in-side of the furnace shell refractory. There is no direct flame impingement on the chips or extreme temperatures that could result in surface oxidation of the chips.

An induced draft fan draws room air into the discharge end of the rotary hearth. This air flows through the rotary hearth in the opposite direction (counter-flow)to the flow of chips. This air removes the water and oil.

Vapors, smoke and dust particles that are generated in the rotary hearth. The exhaust gases, smoke and dust particles are collected in the smoke hood (C) and exit to the pollution control system at point (B) on the smoke hood. Heavy hydrocarbon molecules will be ignited and oxidized in the rotary hearth.

If the temperature in the rotary hearth exceeds set point, cooling air is auto-matically introduced to cool the outside of the rotary hearth. If an excessive amount of hydrocarbons or other combustibles are introduced with the chips into the rotary hearth, water sprays in the smoke hood (C) are automatically initiated to quench the fire.

Dried chips exit the rotary hearth (D) and enter the rotary cooling section (E), where the chips are cascaded through the induced draft, room temperature air, and exit at approximately 300-400A F.

An induced draft fan draws room air into the discharge end of the rotary hearth. This air flows through the rotary hearth in the opposite direction (counter-flow)to the flow of chips. This air removes the water and oil.

Vapors, smoke and dust particles that are generated in the rotary hearth. The exhaust gases, smoke and dust particles are collected in the smoke hood (C) and exit to the pollution control system at point (B) on the smoke hood. Heavy hydrocarbon molecules will be ignited and oxidized in the rotary hearth.

If the temperature in the rotary hearth exceeds set point, cooling air is auto-matically introduced to cool the outside of the rotary hearth. If an excessive amount of hydrocarbons or other combustibles are introduced with the chips into the rotary hearth, water sprays in the smoke hood (C) are automatically initiated to quench the fire.

Dried chips exit the rotary hearth (D) and enter the rotary cooling section (E), where the chips are cascaded through the induced draft, room temperature air, and exit at approximately 300-400A F.

Explore in hindi - थर्मल चिप ड्रायर

Company Details

Capitalizing on its state-of-the-art infrastructure and a pool of dynamic professionals, Arihant Engineers has established itself as a prominent manufacturer and supplier of Aluminium Melting Furnace, E-Waste Recycling Furnace, Hydraulic Tilting Furnace, Tilting Rotary Furnace and Horizontal Ingot Casting Machine. Used in the metal processing industries and recycling plants, these products are engineered using the best grade components and parts. Ever since we ventured into this business in 2007, we have been doing exceptionally well in terms of assuring quality of products and meeting delivery deadlines. We are able to achieve this feat consistently which has helped us build a strong market reputation of our company.

Business Type

Exporter, Manufacturer, Supplier

Employee Count

14

Establishment

2000

Working Days

Monday To Sunday

GST NO

24ABQPJ2589Q1ZR

Seller Details

ARIHANT ENGINEERS

GST

24ABQPJ2589Q1ZR

Proprietor

Mr N. C. Jain

Member Since

2 Years

AddressView on Map

E-28, GIDC, Manjusar, Taluka Savli, Vadodara, Gujarat, 391775, India

Report incorrect details

Related Products

Carts, Designs, Instrumentation and Data Plates, Instrument Panels

EXCEL GRAPHICS PVT. LTD.

Valsad, Gujarat

More Products From This Seller

- Tradeindia

- Industrial Supplies-general

- Thermal Chip Dryer In New Area