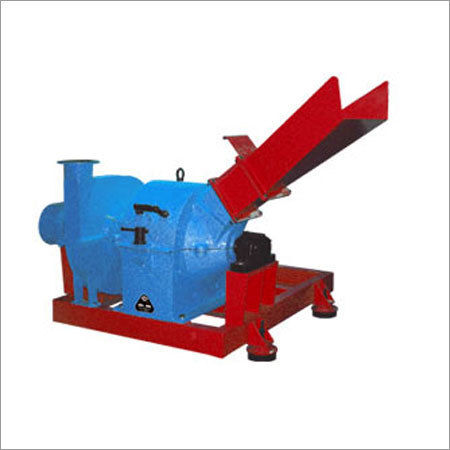

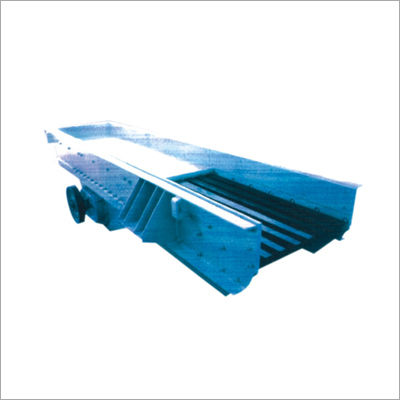

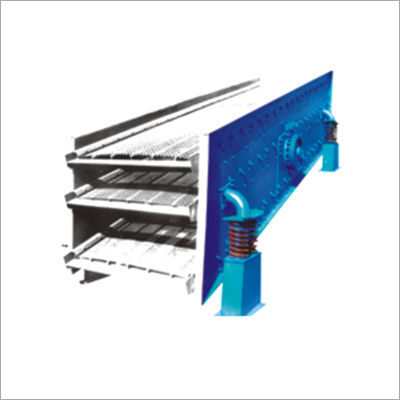

Twin Tube Vibrating Mill

Product Overview

Key Features

Company Details

Business Type

Manufacturer, Supplier

Employee Count

15

Establishment

1998

Working Days

Monday To Sunday

GST NO

24AABCA6087H1ZQ

Seller Details

AMBICA CRUSHTECH PRIVATE LIMITED

GST

24AABCA6087H1ZQ

Director

Mr Urmit Hirubhai Patel

Address

987/2, G.I.D.C. Industrial Estate, Makarpura, Vadodara, Gujarat, 390010, India

tube mill in VadodaraReport incorrect details

Related Products

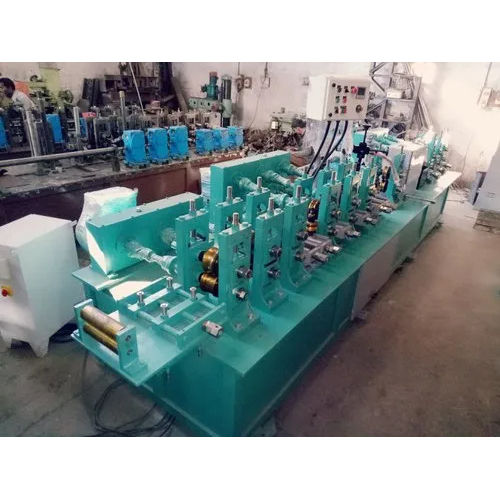

Semi Automatic Hydraulic Erw Tube Mill Machine

Price - 2000000 INR (Approx.)

MOQ - 10 Unit/Units

PAL ENGINEERING WORKS

Vadodara, Gujarat

High Performance Stainless Steel Welded Tube Making Machine - Tube Mill

Price - 1000000 INR (Approx.)

MOQ - 1 Set/Sets

LABH PROJECTS PVT. LTD.

Ahmedabad, Gujarat

Stainless Steel Tube Mill

Price - 1890000 INR (Approx.)

MOQ - 100 Piece/Pieces

SARTHAK INDUSTRIES

Ahmedabad, Gujarat

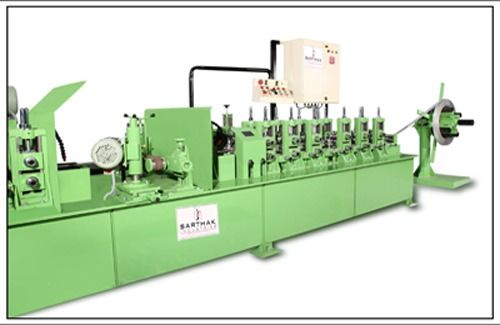

Green Tube Mill Machine

Price - 1100000 INR (Approx.)

MOQ - 1 Unit/Units

Shivam Industries

Ahmedabad, Gujarat

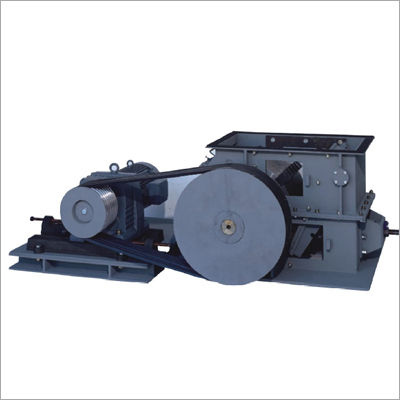

Tube Mill Machinery

Price - 5000000 INR (Approx.)

MOQ - 1 , Piece/Pieces

AXISCO CORPORATION

Ahmedabad, Gujarat

More Products From This Seller

Explore Related Categories

- Tradeindia

- Machineries

- Tube Mill

- Twin Tube Vibrating Mill In Makarpura (Vdr)

Popular Products

Human HairForklift TrucksServo Voltage StabilizerBasmati RiceBackhoe LoaderCarry Bag Making MachineDrum LifterElectric StackerScissor LiftsIndustrial Vibrating ScreenRotameterFlowmeterRotary Air CompressorIndustrial Eto SterilizerRice Packaging MachinesShredding MachineHammer MillAutomatic Labelling MachineDiesel ForkliftAerial Work PlatformStorage Rack SystemEpoxy ResinMild Steel BarStainless Steel SheetsStainless Steel StripsBag Filling MachinesAsphalt PlantsSlat ConveyorOintment PlantPlanetary MixersLadies KurtisLed LightsCctv CameraBall ValveAnti Cancer MedicineAir CompressorIncense SticksSolar LightsGoods LiftsVitrified TilesStainless Steel CoilsPvc PipesPvc Pipe FittingsUpvc PipesUpvc Ball ValvePipe Elbows