Die Cutting Machines

(642 products)

Explore Top die cutting machines Categories

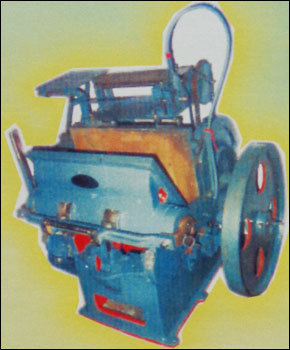

Blue Clam Shell Die Cutting Machine

Price: 490000.00 INR/Set

MOQ - 1 Piece/Pieces

Color - Blue

Product Type - Die Cutting Machine

Weight (kg) - 4 Tonne

19 Years

Business Type: Manufacturer | Exporter

SENIOR PAPER PACKING MACHINERY MFG. CO.

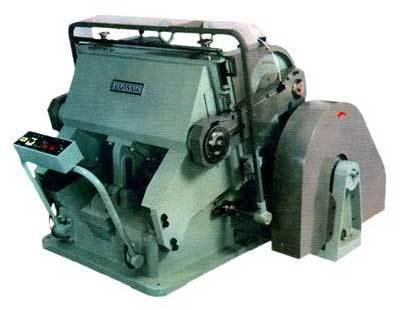

Platen Die Cutting Machine Industrial

Price Trend: 500000.00 - 2350000.00 INR/Number

MOQ - 1 Number

General Use - Industrial

Computerized - No

Automatic - Yes

3 Years

Business Type: Supplier | Trading Company

NAIK AND SONS

Flat Bed Die Cut Punching Machine - Capacity: 950 Pcs/Min

Price: 425000 INR/Unit

MOQ - 1 Unit/Units

Product Type - Flat Bed Die Cut Punching Machine

General Use - Industrial

Capacity - 950 Pcs/min

16 Years

Business Type: Manufacturer | Exporter

S. K. PACKAGE MACHINE

Semi-Automatic Color Printer Die Cutting Machine With Slotting

Price: 2050000 INR/Unit

MOQ - 1 Unit/Units

Type - Die Cutter

Material - Stainless Steel

Computerized - No

20 Years

Business Type: Manufacturer | Exporter

MONU GRAPHICS

Semi-Automatic Honeycomb Board Die Cutting Machine

MOQ - 1 , Unit/Units

Type - Other, Honeycomb board die cutting machine

Material - Stainless Steel

Feature - Heavy Duty Machine, Durable, Less Power Consumable

10 Years

Business Type: Manufacturer | Distributor

SINO TOP MACHINERY MFG. LTD.

Die Cutting Machines - Feature: Low Noise

Price: 850000 INR/Unit

MOQ - 1 Unit/Units

Product Type - Die Cutting Machines

General Use - Industrial

Type - Metal Cutting Machine

1 Years

Business Type: Manufacturer | Supplier

MOKSHA ENGINEERING WORKS

Automatic Full Rotary Die Cutting Machine

Price: 00 INR/Piece

MOQ - 1 Piece/Pieces

4 Years

Business Type: Manufacturer | Exporter

RK LABLE PRINTING MACHINERY PVT LTD

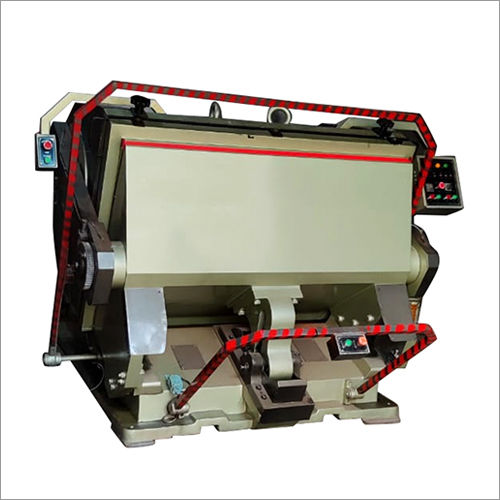

E Cut 1450 E Automatic Die Cutting Machine - Dimension (L*W*H): 10098*5112*2763 Millimeter (Mm)

MOQ - 1 Unit/Units

Product Type - Other

Power Source - Electricity

Operating Type - Automatic

1 Years

Business Type: Manufacturer | Distributor

Suba Solutions Private Limited

Jewellery Die Cutting Press Hand Machine - Color: Black

Price: 14200 INR/Unit

MOQ - 1 Unit/Units

General Use - Industrial

Material - Aluminum

Type - Automatic Cutting Machine

1 Years

Business Type: Manufacturer

OMS Group

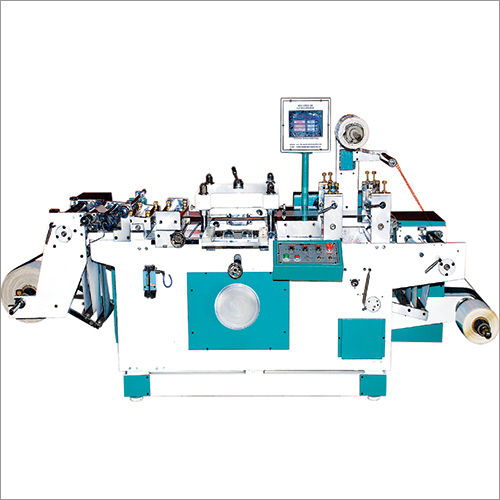

Low Energy Consumption Blank Master Series Label Die Cutting Machine

Price: 950000 INR/Unit

MOQ - 1 Unit/Units

Product Type - Blank Master Series Label Die Cutting Machine

General Use - Industrial

Automatic - Yes

1 Years

Business Type: Manufacturer | Exporter

WEBTECH INTERNATIONAL MACHINERIES

Related Searches

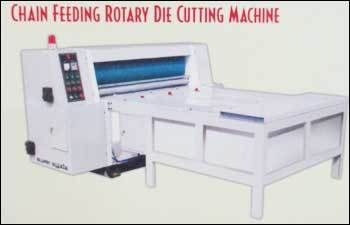

Roll Die Cutting Machine (Model No. Py-950) Diameter: M12*M1.25 Meter (M)

7 Years

Business Type: Manufacturer | Distributor

SAP VARDHMAN MACHINERY PRIVATE LIMITED

Semi Automatic Die Cutting And Creasing Machine Power Source: Hydraulic

MOQ - 10 Unit/Units

Technology - CNC

Power Source - Hydraulic

Operating Type - Semi Automatic

2 Years

Business Type: Distributor | Supplier

BarkTechnologies

Corrugated Sheet Die Cutting Machine Grade: Automatic

Price: 350000 INR/Unit

MOQ - 1 Unit/Units

Grade - Automatic

Type - Die Cutting Machine, Other

Material - Metal

3 Years

Business Type: Manufacturer | Supplier

KHAN MECHANICAL WORKS

Automatic Holographic Die Cutting Machine - Power: 220-440 Volt (V)

Price: 950000 INR/Unit

MOQ - 1 Unit/Units

Power Source - Electricity

Operating Type - Automatic

Power - 220-440 Volt (v)

1 Years

Business Type: Manufacturer | Exporter

Bajaj Holographics India Pvt. Ltd.

Automatic Die Cutting Boards Ejection Rubber Cutting & Installing Machine

Price: 39000 USD ($)/Set

MOQ - 1 Set/Sets

Product Type - Automatic Die Cutting Boards Ejection Rubber Cutting & Installing Machine

General Use - Die Cutting

Type - Automatic Cutting Machine

1 Years

Business Type: Manufacturer | Distributor

Hmw Tech Co., Ltd.

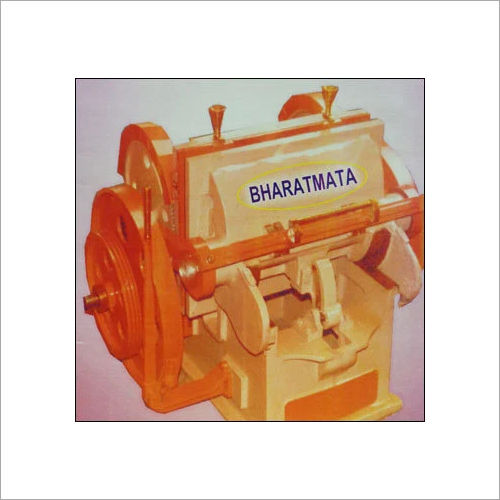

Blue Die Cutting Punching Machine

MOQ - 1 Piece/Pieces

Product Type - Other

Technology - CNC

Power Source - Electricity

2 Years

Business Type: Manufacturer | Supplier

BHARATMATA ENGINEERING WORKS

Printer Dryer Die Cutter Machine

Price: 50000 USD ($)/Set

MOQ - 1 Set/Sets

7 Years

Business Type: Manufacturer | Distributor

EXCELLENCE MACHINERY CO., LIMITED

Heavy Duty Paper Die Cutting Machine

Price: 400000 INR/Unit

MOQ - 1 Unit/Units

Product Type - Paper Die Cutting Machine

Feature - Automatic Feeding, High Torque, Low Noise

1 Years

Business Type: Manufacturer | Distributor

INDIAN PAPER MACHINERIES

Rotary Label Die Cutting Machine (Re-Rdc-300) Warranty: 1 Year

Price: 400000.00 INR/Unit

MOQ - 1 Unit/Units

Product Type - Rotary Label Die Cutting Machine

General Use - Rotary Label Die Cutting Work

Weight (kg) - 450 Kilograms (kg)

11 Years

Business Type: Manufacturer | Supplier

REKHA ENTERPRISES

A Detailed Guide to Die Cutting Machines, Applications, Benefits, Types and More

With die cutting machines we can cut out amazing designs and patterns that are hard to cut manually with scissors. The machine is used in manufacturing units for carving out the complicated designs out of various materials to produce different products. Mostly the die cutting machine is used for making decorative items, packaging materials, and home decor items. These machines have special blades that provide them with such high accuracy to cut out the exact shapes we want. To change the shape and size of the material a worker just needs to change the blade with a new one.

The History of Die Cutting Machines

-

Evolution of Die Cutting Technology

At first, only manual die cutting machines were introduced for cutting holes out of leather material. The workers used to punch holes through different materials like leather by pushing down the handles. These leathers were used to produce high-quality shoes. After a few years cutting machines became popular and were used to cut more complicated shapes and sizes than just punching a hole in leather. Later, the technology used in the machine evolved, and smaller die cutting machines were introduced. With this progress, people can now buy these machines for their personal use. Today, die cutting machines are available in different variants including the electric version of the machine. Industries like electronics packaging, printing, etc. are using this technology to produce a large range of products.

-

Key Innovations and Milestones

Die cutting machines evolved to have advanced features. Their capabilities have led many companies to cross major milestones. For cutting materials more precisely the flatbed and rotary dies were installed in these machines. It is uniquely designed for cutting more detailed patterns or designs from the materials. Also, now hydraulic systems are used to apply pressure for cutting materials. This has increased the performance of the machine and has made it cost-effective. With automatic die cutting machines, the operations become less expensive. The machine consumes less power and delivers high performance to cut desired patterns.

-

The Impact of Digitalization on Die Cutting

When the automatic die cutting machines were introduced they completely changed the process. These advanced machines not only offer higher performance but also save time and money with automation. With die cutting machines the operations have become much faster. This is because of the high precision level and uniquely shaped blades. However, advancement in technology took decades. Firstly manual die cutting machines were introduced that can cut only simple designs and patterns. For cutting fancy designs out of hard materials automatic machines were introduced. With these machines, hundreds of patterns were cut in a few hours. Finally, digital die cutting machines were available in the market with high speed and great performance capabilities. The operators can set parameters and the rest of the work was done by machines. The machine was able to handle all sorts of materials whether soft, delicate, or hard to cut.

What is a Die Cutting Machine?

Die die-cutting machine is an equipment designed for cutting out unique patterns from various materials. It is used in various industries for its speed, precision, and accuracy. The machine is highly versatile and can cut delicate and high-density materials including paper, cardboard, fabric, metal, etc. Its precision comes from the hydraulic pressing system and a specially designed blade called a die. When the hydraulic pressure of the blade it cuts even the metal to carve out special designs.

-

Working of Die Cutting Machines

Die cutting machines work just like a cookie cutter with more power and a special blade. Instead of cutting baked goods, these machines are used to cut paper, cardboard, fabrics, and even metals. The machine has a powerful motor that applies pressure and a specially shaped blade to cut into the material. It cuts various pieces of materials until all the pieces can be assembled to manufacture the product. Also, the force to cut the materials cannot be applied by hand instead a powerful motor is used to produce the required force. Die cutting machines are very accurate and precise with technology to feed the materials automatically.

Key Components of A Die Cutting Machine:

- Die: A strong blade with a unique shape to cut various designs from the material.

- Cutting platform: A flat surface to place the material for cutting designs or patterns.

- Rollers or Press Plate: The rollers apply pressure on the blade or die to cut the materials.

- Control system: It involves all the functions that control the die cutting machine whether it is a manual, automatic, or digital machine.

- Feeding Mechanism: It continuously delivers the material to cut in the die cutting machine.

Here are the Common Types of Die Cutting Machines

-

Manual Die Cutting Machine

Manual die cutting machines are used for small operations or personal projects. With manual die cutting machines the operators apply pressure manually to cut designs with materials. Paper, cardboard, and fabric are the materials that these machines can easily cut. There are many other benefits of using die cutting machines including low expenses, compact size, and ease of use. For these reasons manual die cutting machines are commonly used for scrapbooking, making cards, and packaging materials.

-

Digital Die Cutting Machines

The digital die cutting machines are controlled with computers. Operators can customize the settings for the results and the machine will perform according to those settings. These types of machines can cut complicated designs and patterns from paper, fabric, vinyl, etc. Also, the users can download and send different patterns to the machine for cutting the exact shapes and sizes. The machine can complete large orders in a short amount of time with great accuracy and speed.

-

Industrial Die Cutting Machines

Die cutting machines that are used in industrial companies can cut everything like paper, fabric, foam, rubber, and metal sheets. They are used for producing large orders with high speed and accuracy to help businesses increase their production capacity. The parts of these machines are easy to replace for every job like shaped blade or die. They have great force and a high-quality blade to cut through materials easily. Also, industrial machines have automatic material feeding which increases their performance. The materials are placed under the blade continuously without delay for cutting different designs.

-

Flatbed vs. Rotary Die Cutting Machines

A flatbed die cutting machine cuts different types of materials just like a punching machine. It presses towards the materials with a hydraulic system and cuts out a specific shape. Flatbed dies are less expensive than rotary dies because they have a slow production speed. These dies can be cut through tough materials like metal sheets, plastic, and any other thick materials. It's just that these machines take longer to set up for production.

Whereas rotary die cutting machines are powered by electricity and have a cylinder-shaped die or blade to cut the materials. These types of die cutting machines have a fast production rate and can cut a large number of pieces with every batch. Rotary dies have more precision and accuracy than flatbed dies and they can perform more functions like printing and lamination.

-

Comparison of Different Die Cutting Technologies

There are various types of die cutting machines in the market. Each machine is designed carefully for a specific task. For example, manual die cutting machines are the best for small operations that require low quantities. In these types of tasks saving costs on operations is the main focus. On the other hand, there are digital die cutting machines that are controlled by computers and used for mass production. They have great precision and accuracy with a high return on investment in the long run.

Uses of Die Cutting Machines

-

Packaging Industry

Die cutting machines are used in this industry for creating custom packaging materials like boxes, cartons, etc. With unique packaging materials, the brands impress their customers and increase sales. Also, the accuracy of the machine provides beautiful designs and improves the quality of the product. Also, the packaging industry produces custom designs in bulk for the brands. They require speed and precision of the die cutting machines to fulfill bulk orders within the promised time.

-

Textile and Apparel Industry

The textile industry uses die cutting machines for cutting fabrics into beautiful designs. Their products include a wide range of clothes and carry bags. But the industry simply doesn't produce a simple range, they create custom designs. Die cutting machines cut complicated designs for various brands that the textile industry delivers. Using the machine’s help they craft a collection of beautiful clothes and home textiles. The materials that the machine easily carves through are cotton, silk, leather, and synthetic fiber.

-

Automotive

Die cutting machines are used in this industry for making engine seals, insulation layers, gaskets, and much more. These machines create them in specific shapes and sizes for different vehicles. Die cutting is a less expensive method in the automotive industry for creating these parts. The accuracy of this machine provides high-quality vehicle parts to increase performance.

-

Crafting and Scrapbooking

Manual die cutting machines are the best for personal use. They incur less expense and are used for small production tasks. This is why, crafting and scrapbooking industries use them for cutting custom designs. Die cutting machines make specific cuts from paper, cardboard, and vinyl to produce decoration items, packaging materials, and cards. The machine provides high accuracy and speed to create these items in less time.

-

Electronics and Medical Devices

These industries use die cutting machines as it is a less expensive solution for producing high-quality equipment. The machine provides specific shapes of materials in different pieces that are later assembled into electronics or medical devices. The materials used in these industries are very soft and delicate and only die cutting machines can cut out specific shapes from these materials. Also, the machine can repeat the process for long hours to increase production capacity with a single setting.

Design and Features of Die Cutting Machines

-

Cutting Precision and Accuracy

There are many industries that use die cutting machines for their high accuracy. These machines cut custom designs, patterns, and shapes out of various materials. Whether the nature of the material is delicate or high density the machine has a special blade to deal with it. Also, the product's quality depends on the accuracy of the die cutting machine to deliver performance. However, the machine can perform great with the help of its die or blade. There are various types of blades available for it including the cylindrical one that cuts various pieces of the same product. These pieces are then assembled into a complete product.

-

Material Compatibility

Die cutting machines are versatile and support a large number of materials. These materials can be delicate, hard to cut, and even rubbery which increases the demand for these machines. Moreover, the die cutting machines are customizable to maintain compatibility with other materials. These customizations include adjustable pressure, change of blades, and regulating motor speed. However, these adjustments are only made when the material has a different thickness and density than the previous one. This system allows the machine to cut smooth and precise designs in automatic mode.

-

Automation and Digital Integration

Automatic die cutting machines have many benefits over manual ones. They can be controlled with a computer that reduces the manual hard work. Also, there are many customization options for automatic die cutting machines to make them compatible with every type of material. Without the need for manual controls, the die cutting machine can help in mass production in less time. Moreover, there are various types of systems that are infused with these machines like CNC controls, custom user interfaces, etc.

-

Safety Features in Die Cutting Machines

A company is responsible for the safety of its employees in the workplace environment. In industrial spaces, workers are more exposed to accidental situations. For which the company prepares itself with effective measures like giving proper training, hiring safety tools, and using high-quality machines. This is the reason why high-quality die-cutting machines are used for producing materials. These machines allow smooth operations without much maintenance requirement. They perform repeated tasks so that workers don’t have to strain themselves. Also, modern machines are designed with safety features like emergency stops, overload warnings, etc. to avoid accidents.

-

Customization Options

Die cutting machines are highly customizable to cut patterns from every kind of material. The machine is produced using the best quality parts and components. It avoids scratches and has low downtime. The parts of the machines are easy to upgrade which increases its production capacity. The customizations include cutting blades, applied pressure, automatic feeding system, etc. Moreover, many sellers offer pre-customized machines built for specific industries. These custom-made machines have increased speed and accuracy for various applications.

Benefits of Using Die Cutting Machines

-

Efficiency and Productivity

Die cutting machines are designed to offer precise cutting and speed. They are highly reliable no matter which type of materials are used to cut designs. Whether the company is using manual or automatic die cutting machines, it offers productivity and a safe working environment. The machine has customizable parts for cutting different kinds of materials. Die cutting machines can carve accurate designs from delicate paper-like materials to hard-to-cut metals. Also, the machine saves both time and money with its high-speed capabilities. It reduces the need for manual work and the wastage of resources.

-

Cost-Effectiveness

With an automatic die cutting machine the tasks are completed with high speed and accuracy. The need for manual labor is not required and it saves a lot of resources to complete the tasks. With reduced labor expenses and mass production, a company saves money and generates more revenue. Also, high-quality machines require low maintenance and have less downtime which also saves operational costs. The quality of the products also increases along with its demand in the market. Moreover, with saved expenses, companies can invest in fields with more business opportunities.

-

Versatility in Applications

Die cutting machines are very versatile to handle every kind of cutting material. They can cut through delicate and soft materials like paper and thin fabric as well as high-density metals. The machine has various customizable options like various cutting blades and adjustable pressure for cutting these materials with ease. The companies take advantage of this capability and use die cutting machines for multiple applications. They save on expenses and eliminate the need for labor work.

-

Quality and Consistency

The main benefit of investing in a die cutting machine is the constant quality we get. The machine maintains consistent quality from the start of the operations to the end. It maintains accuracy and precision in every single cut it makes and crafts materials. Automatic die cutting machines have the latest technology like high-quality blades, powerful motors, etc. to deliver performance. Consistency is maintained throughout the production process with high-quality parts. The machine requires no manual work and completes the operations in a single command.

-

Speed of Production

Die cutting machines are specifically designed to cut complicated designs with speed. They help increase the production capacity with powerful components. With simple instructions from the operators, the die cutting machines can complete the whole process with high speed. This allows a business to deliver bulk orders within the promised time. Moreover, with speed, the quality of the product is never compromised. Instead, the machine makes the operations cost-effective by reducing the wastage of the materials.

Safety and Compliance Standards

-

OSHA Regulations for Die Cutting Machines

OSHA regulations are the safety guidelines for all industrial machines. Under these instructions, a machine should be designed with safety features for a safe work environment. As per these guidelines, the machines should have an emergency stop function, cover guards, etc. that will help avoid accidents.

-

Best Practices for Safe Operation

There are some safety practices in the industrial sector for the machines. These practices are performed to avoid any type of mishappening in the facilities. To work in a more safe environment, operators should have regular training, machines should be checked before operations, workers should wear PPE kits, and more.

-

Maintenance and Inspection Guidelines

Industrial machines are used for several hours at peak performance. These machines provide higher productivity and consistent quality. However, without regular maintenance and inspections, these machines can have complete failure. To solve this problem every industry must conduct regular maintenance and inspections. By performing these activities workers can find out about any problem with machines beforehand. This practice avoids any type of hazardous situation that can occur in the future.

-

Environmental Considerations

Every industrial unit must comply with environmental regulations. These rules guide them to reduce wastage and practice energy-saving methods. Moreover, they must use chemicals that are safe to use and reduce noise pollution.

Things to Consider When Purchasing a Die Cutting Machine

-

Budget and Cost Analysis

Before choosing a die cutting machine it is important to consider your budget. The motive is to get a machine that is worth its value. Also, it prevents a business from spending more than it requires and allows hiring a high-quality product. Although the initial value of the machine will be higher, in the long run, a business can get great returns on its investments. You should consider all the costs that will be repeated in the future including maintenance and operational costs.

-

Space and Facility Requirements

Compare the available space your facility has and the space you will require to set up the machine. Die cutting machines come in various shapes and sizes so you must choose the one that fits your floor space. Moreover, you must have much space left even after installation to move around the machine for maintenance and repairs.

-

Technical Support and Training

Choose the suppliers for your die cutting machine carefully. They must provide training, technical support, and customer service to better operate the machine. The way you operate the machine will affect its performance and lifespan. Reliable customer support and training will ensure that your machine offers optimal performance.

-

Compatibility with Existing Processes

Die cutting machines with advanced technology are specially designed to integrate with existing production systems to save unnecessary expenses. The successful integration saves the company from spending on costly modifications.

Client Testimonials & Reviews

Die Cutting Machines Price List

| Product Name | Expected Price |

|---|---|

| Jewellery Die Cutting Press Hand Machine | 14200 |

| Die-Cutting Machines | 500000 |

| Automatic Holographic Die Cutting Machine | 950000 |

| Die Cutting Machine | 950000 |

| Die Cutting And Creasing Machine | 500000 |

| Die Cut Machine | 400000 |

| Platen Die Cutting Machine | 400000 |

| Die Cutting Machines | 190000 |

| Die Cutting Machines | 850000 |

| Industrial Die Cutting Machine | 25000 |

This Data was Last Updated on 2024-09-30

Die Cutting Machines Manufacturers | Suppliers in India

| Company Name | Location | Member Since |

|---|---|---|

| Friends Engineering Corporation | New Delhi, India | 22 Years |

| Monu Graphics | Faridabad, India | 20 Years |

| Associated Industrial Corporation | Amritsar, India | 20 Years |

| Senior Paper Packing Machinery Mfg. Co. | Amritsar, India | 19 Years |

| S. K. Package Machine | Vapi, India | 16 Years |

| Nmc Engineers | New Delhi, India | 13 Years |

| Rekha Enterprises | Mumbai, India | 11 Years |

| Sino Top Machinery Mfg. Ltd. | Suzhou, China | 10 Years |

| Box Mania Pvt. Ltd. | Sonipat, India | 8 Years |

| Sap Vardhman Machinery Private Limited | Delhi, India | 7 Years |

FAQs Related to Die Cutting Machines

- Friends Engineering Corporation

- Monu Graphics

- Associated Industrial Corporation

- Senior Paper Packing Machinery Mfg. Co.

- S. K. Package Machine

- Nmc Engineers

- Rekha Enterprises

- Sino Top Machinery Mfg. Ltd.

- Box Mania Pvt. Ltd.

- Sap Vardhman Machinery Private Limited

- Mumbai

- Delhi

- Chennai

- Pune

- Bengaluru

- Kolkata

- Hyderabad

- Jaipur

- Ahmedabad

- Rajkot

| Company Name | Currency | Product Name | Price |

|---|---|---|---|

| OMS Group | INR | Jewellery Die Cutting Press Hand Machine | 14200 |

| V.S. RESOURCES | INR | Die-Cutting Machines | 500000 |

| Bajaj Holographics India Pvt. Ltd. | INR | Automatic Holographic Die Cutting Machine | 950000 |

| Bajaj Printpack Machineries Pvt. Ltd. | INR | Die Cutting Machine | 950000 |

| PRIMA MACHINERY CO. | INR | Die Cutting And Creasing Machine | 500000 |

| Hardev industries | INR | Die Cut Machine | 400000 |

| AMRITSAR WOOD & MACHINERY WORKS | INR | Platen Die Cutting Machine | 400000 |

| NS ENTERPRISES | INR | Die Cutting Machines | 190000 |

| MOKSHA ENGINEERING WORKS | INR | Die Cutting Machines | 850000 |

| SANTHA ENTERPRISES | INR | Industrial Die Cutting Machine | 25000 |

- SENIOR PAPER PACKING MACHINERY MFG. CO.

- NAIK AND SONS

- S. K. PACKAGE MACHINE

- MONU GRAPHICS

- SINO TOP MACHINERY MFG. LTD.

- MOKSHA ENGINEERING WORKS

- Suba Solutions Private Limited

- OMS Group

- WEBTECH INTERNATIONAL MACHINERIES

- Box Mania Pvt. Ltd.

- Safire Machinery Company Private Limited

- AGARWAL TRAFIN PRIVATE LIMITED

- LOTUS INDUSTRIES

- KHAN MECHANICAL WORKS

- JENAN OVERSEAS EXPORTS

- Bajaj Holographics India Pvt. Ltd.

- SENIOR PAPER PACKING MACHINERY MFG. CO.

- S. K. PACKAGE MACHINE

- MONU GRAPHICS

- ASSOCIATED INDUSTRIAL CORPORATION

- EXCELLENCE MACHINERY CO., LIMITED

Related Categories

Rotary Die Cutting Machine

Printing Slotting Die Cutting Machine

Flat Bed Die Cutting Machine

Die Board Laser Cutting Machine

Abrasive Disc Cutting Machine

Veneer Cutting Machine

Programmable Paper Cutting Machine

Machine Cutting Tools

Chips Cutting Machine

Plastic Cutting Machine

Industrial Bar Cutting Machine

Battery Cutting Machines

- Tradeindia

- Cutting Machine

- Die Cutting Machines

Related Categories

Popular Products

Human HairForklift TrucksServo Voltage StabilizerBasmati RiceBackhoe LoaderCarry Bag Making MachineDrum LifterElectric StackerScissor LiftsIndustrial Vibrating ScreenRotameterFlowmeterRotary Air CompressorIndustrial Eto SterilizerRice Packaging MachinesShredding MachineHammer MillAutomatic Labelling MachineDiesel ForkliftAerial Work PlatformStorage Rack SystemEpoxy ResinMild Steel BarStainless Steel SheetsStainless Steel StripsBag Filling MachinesAsphalt PlantsSlat ConveyorOintment PlantPlanetary MixersLadies KurtisLed LightsCctv CameraBall ValveAnti Cancer MedicineAir CompressorIncense SticksSolar LightsGoods LiftsVitrified TilesStainless Steel CoilsPvc PipesPvc Pipe FittingsUpvc PipesUpvc Ball ValvePipe Elbows