Wet Mix Paver

(69 products)

Semi-Automatic Wet Mix Paver Finisher

Price: 2200000 INR/Set

MOQ - 1 Set/Sets

Color - Yellow

Type - Pavers

Capacity - 150 to 200 tons/hour Ton/day

13 Years

Business Type: Manufacturer | Distributor

KESAR ROAD EQUIPMENTS ( INDIA ) PVT. LTD.

Automatic Sensor Paver

Price: 2000000.00 INR/Unit

MOQ - 1 Unit/Units

Color - Yellow

Material - MS

Computerized - No

11 Years

Business Type: Manufacturer | Distributor

UNIPAVE ENGINEERING PRODUCTS

Semi-Automatic Asphalt Cum Wet Mix Paver Finisher

Price: 1950000 INR/Unit

MOQ - 1 Unit/Units

Color - Yellow and Black

Type - Asphalt Mixers

Material - Stainless Steel

Response Rate: 77.78%

Business Type: Manufacturer | Supplier

ASHTVINAYAK INDUSTRIES

Wet Mix Paver

Price Trend: 38.00 - 90.00 INR/Piece

MOQ - 1 Piece/Pieces

Material - Mild Steel

Business Type: Manufacturer | Exporter

D. M. OVERSEAS

Wet Mix Paver Finisher

Price Trend: 1600000.00 - 3500000.00 INR/Unit

MOQ - 1 Unit/Units

Business Type: Manufacturer | Distributor

PERFECT ENGINEERS

Related Searches

5 Years

Business Type: Manufacturer | Distributor

CONINFRA MACHINERY PRIVATE LIMITED

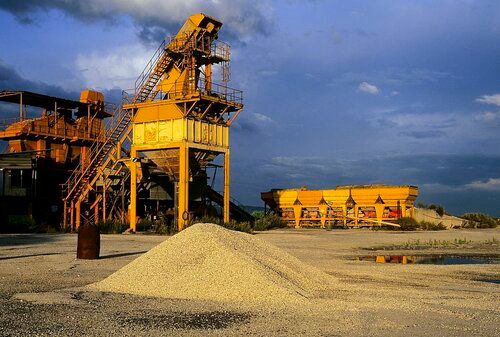

Wet Mix Paver: An Overview

A wet mix paver is a road construction equipment that plays a crucial role in creating and maintaining plain and smooth surfaces of highways, airport runways, and other concrete surfaces. This road construction equipment is useful for applying layers of dry-lean concrete ( it combines aggregate and cement in a 14:1 ratio) for preparing the GSB surface. It is also instrumental in laying wet mix macadam (graded, crushed, and granular aggregate which is mixed with water in specific proportion to attain a dense texture). The mixture is laid and spread on the granular sub-base layer (GSB) one or multiple times to achieve the desired surface of roads. The design and mechanism of a wet mix paver conform to MoRTH (Ministry of Road Transport & Highways, Government of India).

How does a wet mix paver work?

Automatic or semi-automatic wet mix paver consists of several units and each of these units has a significant role in its smooth running. To understand its operating process, one should have a clear understanding about its standard components and their roles.

1. Based on the project requirement, this road construction equipment is available in diesel-fueled or water-cooled engines of specific horsepower along with an electrical starting system.

2. Its hydraulic hopper is useful for the transportation of asphalt concrete to its conveyor.

3. Its twin bar conveyors are instrumental in feeding the material to its augers from the hopper.

4. Power steering of this road construction equipment simplifies its controlling procedures. All the parameters of this equipment are controllable from its single dashboard for the convenience of the operator.

5. Hydraulic telescopic screed of wet mix paver helps to maintain the specific thickness of asphalt -concrete -layer by precisely removing excess material.

6. Chassis of this road construction equipment strengthens its structure and improves its stability.

Usually, for spreading the first layer of asphalt concrete, a motor grader is the ideal choice. Its hydraulic blade is capable of adjusting the thickness of the wet mix macadam layer as per the slope of a specific surface. Its design includes loading hoppers, a material distribution unit, and a compaction-controlling section to attain flawless texture of the finished surface.

The wet mix paver starts its compaction process by using a vibratory compactor immediately after the completion of lying layers of wet mix macadam. Width-by-width movement of the vibratory compactor is maintained from the lower edge to the upper edge of the applied WMM layer. The second layer of wet mix macadam is spread only after checking the quality of the first WMM layer. The final compaction of the WMM surface takes around 24 hours to dry.

Types of Wet Mix Pavers

Wet mix pavers are available in different models with various specifications. Parameters like travel speed, screed design, operating width, fuel tank capacity, and other attributes of these road construction machines vary as per their design. These include:

1. Semi-automatic Wet Mix Paver Finisher

This road construction equipment features noiseless operation. Its advanced features include-

a. Hydraulically controlled telescopic screed for precise removal of excess WMM material to maintain the required thickness of the spread layer

b. Power steering and air brake-based design

c. Single dashboard-based operation controlling arrangement

2. Semi-automatic Asphalt Cum Wet Mix Paver Finisher

This version of the wet mix paver is suitable for WMM and bitumen-spreading purposes. It uses LPG fuel or an oil-based burner as the source of heat of its screed for maintaining homogeneity and a standard thickness of the applied layer.

3. Semi Hydro Wet Mix Paver

This version of wet mix paver operates semi-hydraulically to precisely control the paving process.

Applications of Wet Mix Pavers

Wet mix pavers have a broad scope of applications. These road construction equipment are suitable for constructing roads, highways, driveways, walkways, and sidewalks. The specialty of wet mix pavers is that these equipment maintain high precision while preparing wet mix macadam. Specific proportion is maintained while blending water, graded and crushed aggregates, and cement to attain desired texture of the spread layer post-compaction. The aesthetics of developed roads and driveways is another important factor that wet mix pavers help to achieve and maintain.

Advantages of Using A Wet Mix Paver

Wet mix paver is effective in constructing roads, commercial parking areas, residential parking spaces, airport runways, warehouse floors, factory floors, and highways with improved surfaces. There are several advantages to this road construction equipment. These are mentioned below:

1. Its user-friendly mechanism not only boosts its productivity but also upgrades the standard of construction.

2. This road construction equipment maintains high accuracy in maintaining the proportion of raw materials and their mixing to achieve the desired result.

3. It can be relocated to different construction sites.

4. High output of wet mix paver ensures higher return in any construction project at minimal investment.

5. Hardware -parts of this equipment are made as per global manufacturing norms.

6. Lubricated components of this equipment help to minimise their downtime rate.

Client Testimonials & Reviews

Wet Mix Paver Price List

| Product Name | Expected Price |

|---|---|

| Wet Mix Paver | 2500000 |

| WM-6 Wet Mix Paver | 2500000 |

| Apollo Wet Mixing Paver | 2200000 |

| Crawler Mounted Sensor Paver Finisher | 2000000 |

| Asphalt cum Wet Mix Paver Finisher | 1950000 |

| Sensor Paver | 2000000 |

| Mechanical Wet Mix Paver | 2000000 |

| Wet Mix Paver Finisher | 2200000 |

This Data was Last Updated on 2024-09-25

Wet Mix Paver Manufacturers | Suppliers in India

| Company Name | Location | Member Since |

|---|---|---|

| Universal Engineers | Ahmedabad, India | 19 Years |

| Himalaya Engineering Co. | Mehsana, India | 19 Years |

| Kesar Road Equipments ( India ) Pvt. Ltd. | Mehsana, India | 13 Years |

| Unipave Engineering Products | Ahmedabad, India | 11 Years |

| Aadesh Industries | Mehsana, India | 7 Years |

| S K Engineering | New Delhi, India | 6 Years |

| Coninfra Machinery Private Limited | Ahmedabad, India | 5 Years |

| Terra Equipment | Mehsana, India | 5 Years |

| Rudra Engineers | Ahmedabad, India | 4 Years |

| A.k Engineering | New Delhi, India | 4 Years |

FAQs Related to Wet Mix Paver

Specifications like engine output, operating height and width, paving speed, travel speed, hopper capacity, and a fuel tank capacity of wet mix pavers vary from model to model. It is, therefore, necessary to choose the right version of wet mix paver as per the budget and size of the paving project.

To extend the longevity of the wet mix paver, its hardware -parts, and components should go through regular checking procedures. One should verify whether its hydraulic system, screed, and vibratory compactor are functioning properly or not. Importance needs to be given to checking the hydraulic fluid storage level of this equipment. In case there is a blockage in its internal parts, immediate action needs to be taken to handle the situation. Operating speed and paving direction are the other two factors that one should consider while doing maintenance checking procedures.

Wet mix paver spreads dry-lean concrete by combining higher aggregate and lower cement content to attain a specific texture of the granular sub-base layer. Spreading of graded, crushed and granular aggregate-based macadam is another task that it performs with utmost precision. The thickness of the spread concrete layer depends on the slope specifications of a particular surface. The vibratory compactor of the wet mix paver plays a significant role in attaining the perfection of the finished surface.

Wet mix paver handles wet cast concrete that has a liquid-based texture. Due to its high slump rate, one can pour wet mix concrete directly from the truck or the hopper or mixer. A dry mix paver is suitable for handling dry cast concrete with slump-free content for the presence of a minimal amount of water in it. Wet mix pavers and dry mix pavers have applications in residential projects. But for large-scale commercial projects, a dry mix paver is suitable for its higher strength and better load capacity than a wet mix paver.

- Tradeindia

- Road Construction Machinery

- Wet Mix Paver

Related Categories

Popular Products

Human HairForklift TrucksServo Voltage StabilizerBasmati RiceBackhoe LoaderCarry Bag Making MachineDrum LifterElectric StackerScissor LiftsIndustrial Vibrating ScreenRotameterFlowmeterRotary Air CompressorIndustrial Eto SterilizerRice Packaging MachinesShredding MachineHammer MillAutomatic Labelling MachineDiesel ForkliftAerial Work PlatformStorage Rack SystemEpoxy ResinMild Steel BarStainless Steel SheetsStainless Steel StripsBag Filling MachinesAsphalt PlantsSlat ConveyorOintment PlantPlanetary MixersLadies KurtisLed LightsCctv CameraBall ValveAnti Cancer MedicineAir CompressorIncense SticksSolar LightsGoods LiftsVitrified TilesStainless Steel CoilsPvc PipesPvc Pipe FittingsUpvc PipesUpvc Ball ValvePipe Elbows