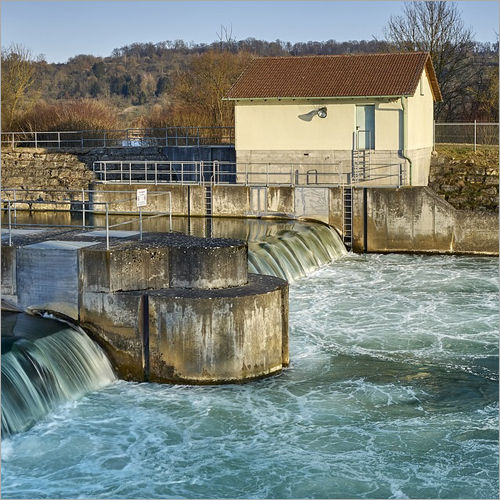

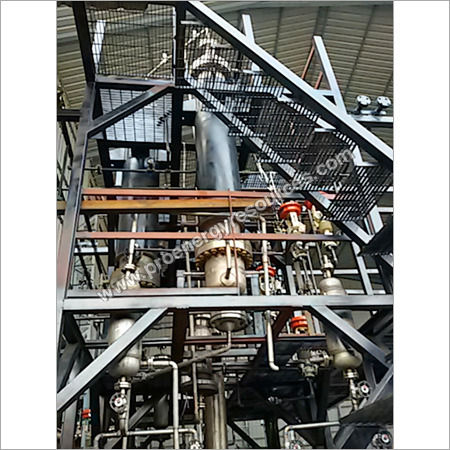

Breweries Plant

Product Overview

Key Features

Company Details

Focusing on a customer-centric approach, PROENERGY RESOURCES PVT. LTD. has a pan-India presence and caters to a huge consumer base throughout the country. Get Wastewater Treatment Plants from PROENERGY RESOURCES PVT. LTD. at Trade India quality-assured services.

Business Type

Exporter, Manufacturer, Service Provider, Supplier

Employee Count

35

Establishment

2011

Seller Details

PROENERGY RESOURCES PVT. LTD.

Managing Director

Mr. Kiran Thombare

Address

4th Floor, Farena Park, Magarpatta City Road, Near Kharadi Bypass, Hadapsar, Pune, Maharashtra, 411013, India

Wastewater Treatment Plants in PuneReport incorrect details

Related Products

Full Automatic Commercial Wastewater Treatment Plants

Price - 1000000 INR (Approx.)

MOQ - 1 Unit/Units

DHARA WATER TECH PRIVATE LIMITED

Pune, Maharashtra

Waste Water Treatment Plant Application: Industrial

MOQ - 1 Unit

SIDDHIVINAYAK ELECTRIC MECHANICAL AND FABRICATION

Pune, Maharashtra

Petroleum Wastewater Treatment Plant Density: 0.79 Gram Per Cubic Centimeter(G/Cm3)

ELECTRO PROCESSORS

Pune, Maharashtra

Wastewater Treatment Plant Repairing And Installation Service

MOQ - 1 Unit

XYLEM ENVOCARE INDIA PRIVATE LIMITED

Pune, Maharashtra

Full Automatic Residential Wastewater Treatment Plant

Price - 750000 INR (Approx.)

MOQ - 1 Plant/Plants

Ecoglobe Enviro Solutions

Pune, Maharashtra

Packaged Wastewater Treatment Plant, Usage/Application: Textile Mills

PANSE CONSULTANTS

Pune, Maharashtra

More Products From This Seller

- Tradeindia

- Wastewater Treatment Plants

- Breweries Plant In Hadapsar

Recommended Products

Popular Products

Human HairForklift TrucksServo Voltage StabilizerBasmati RiceBackhoe LoaderCarry Bag Making MachineDrum LifterElectric StackerScissor LiftsIndustrial Vibrating ScreenRotameterFlowmeterRotary Air CompressorIndustrial Eto SterilizerRice Packaging MachinesShredding MachineHammer MillAutomatic Labelling MachineDiesel ForkliftAerial Work PlatformStorage Rack SystemEpoxy ResinMild Steel BarStainless Steel SheetsStainless Steel StripsBag Filling MachinesAsphalt PlantsSlat ConveyorOintment PlantPlanetary MixersLadies KurtisLed LightsCctv CameraBall ValveAnti Cancer MedicineAir CompressorIncense SticksSolar LightsGoods LiftsVitrified TilesStainless Steel CoilsPvc PipesPvc Pipe FittingsUpvc PipesUpvc Ball ValvePipe Elbows