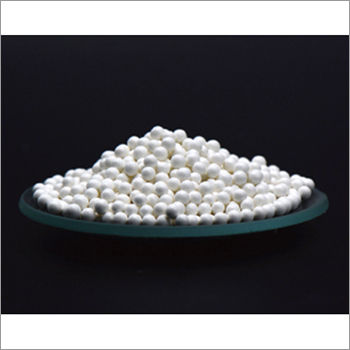

Ladle Lining Alumina Length: 3-5 Millimeter (Mm)

Get LatestPrice

Get Best Deals

Ladle Lining Alumina ( ADLAD-AL) We are offering a wide assortment of Ladle Lining Material (ADLAD-AL) that is made available in several...View Product Details

Product Overview

Key Features

Ladle Lining Alumina ( ADLAD-AL) We are offering a wide assortment of Ladle Lining Material (ADLAD-AL) that is made available in several quantities as per requirement. The offered product is specially used for lining the ladles used in foundries for transferring the molten metal from furnace. Our ingenious professionals formulate this product with the use of supreme quality silica, quartz and other ceramic binders by employing sophisticated methods. Tested on defined parameters of quality, this Ladle Lining Materials can be availed at industry leading rates. Features: Easy to applySafe to useLonger shelf lifePrecise composition Preparation of Mixtures Supplied in dry form using air-tight bagsMaterial should be unpacked on clean surface for further usageMix well before addition of waterAfter mixing required amount of water should be added that is around 6-8% depending on the consistency requiredMinimum amount of water should be added so that lining does not crack while preheatingAfter water addition, it should mix again thoroughlyFor the development of full plasticity, mixture should be covered with wet gunny bags for 8 to 12 hours Important Note: One should take care of removal of strings while unpacking material from bags so that it will not mix with material. Remove this kind of material which will burn, as this will create cavity on heatingHot metal will enter such cavity and will damage lining resulting in reduction of lining life. Method of Applications Put small handballs made of the mixture in ladle to be lined.Surface should be prepared of required thickness (Thickness will depend on capacity of the ladle varying from 2 to 6 or more).For proper compressing of the applied material, surface should be rammed with wooden hammer It is advised for bigger size ladle there should be a steel former prepared with complete ramming while applying material.It should be perfectly dried so that extra water evaporates.Dried ladle should be preheated with wood fire before using the same. Technical Specifications AI2O3:50-55% Min.SiO2: 40-45% Min.Grain size: 0 to 4mmPacking: 50kg bag.

Explore in hindi - लैडल लाइनिंग एलुमिना

Company Details

Business Type

Exporter, Manufacturer, Supplier, Trading Company

Employee Count

5

Establishment

1991

Working Days

Monday To Sunday

GST NO

24AADFA6706A1Z6

Seller Details

A

ADORE MULTILINE PRODUCTS

GST

24AADFA6706A1Z6

Rating

4

Partner

Mr. Kshitij Badheka

Address

506, Spectrum, Near G.P.O., Salapose Road, Ahmedabad, Gujarat, 380001, India

Foundry Raw Material & Equipment in AhmedabadReport incorrect details

More Products From This Seller

- Tradeindia

- Foundry Raw Material & Equipment

- Ladle Lining Alumina In Salapose Road

Recommended Products

Popular Products

Human HairForklift TrucksServo Voltage StabilizerBasmati RiceBackhoe LoaderCarry Bag Making MachineDrum LifterElectric StackerScissor LiftsIndustrial Vibrating ScreenRotameterFlowmeterRotary Air CompressorIndustrial Eto SterilizerRice Packaging MachinesShredding MachineHammer MillAutomatic Labelling MachineDiesel ForkliftAerial Work PlatformStorage Rack SystemEpoxy ResinMild Steel BarStainless Steel SheetsStainless Steel StripsBag Filling MachinesAsphalt PlantsSlat ConveyorOintment PlantPlanetary MixersLadies KurtisLed LightsCctv CameraBall ValveAnti Cancer MedicineAir CompressorIncense SticksSolar LightsGoods LiftsVitrified TilesStainless Steel CoilsPvc PipesPvc Pipe FittingsUpvc PipesUpvc Ball ValvePipe Elbows