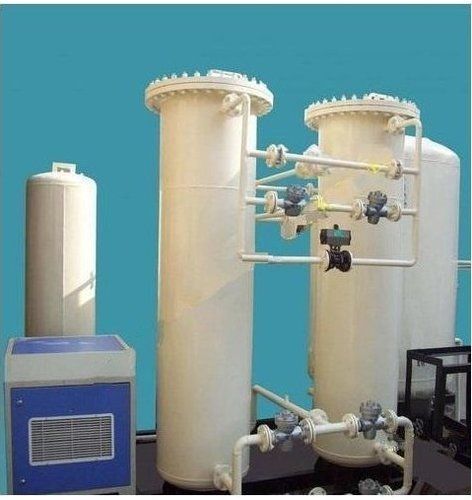

We, SAI SATYA ENGINEERS, are India's leading manufacturer and supplier of PSA Oxygen Gas generator. We have ultra-modern in-house facility and expertise for developing of varied Adsorbers, Columns, Pressure Vessels, Reactors, Heat Exchangers, Tanks etc. Our offered Oxygen Plant finds its applications in Pharmaceutical Industry, Lamps Industry, Glass Industry, T.V. Picture Tube Manufacturing Industry, Steel Industry, Chemicals & Petrochemical and Water Treatment plants. Moreover, clients can avail this Oxygen Plant from us at negotiable prices in varied specifications.Other Detail:The Process of VPSAIn this design there are 2 Molecular sieves vessels which cycle alternately-in Production and in Regeneration. Feed air pressure is generally 1.1 to 1.5 Bar (A) which gives Oxygen production at 1.05 to 1.3 Bar (A). Regeneration of Molecular sieves is done by a vacuum pump at 210mm Hg Absolute pressure. The waste gas is 85% Nitrogen and 15% Oxygen which is vented to atmosphere through a silencer. Product Oxygen gas purity is 90 to 95%. A typical VPSA system usually comprises the following: Vacuum blower A Centrifugal feed air blower An oxygen surge tank Two adsorbent vessels Switching valves Computer controls O2 Compressors As mentioned, VPSA produces gaseous products at purities between 90 and 95%. In case of oxygen, the impurities are usually nitrogen and argon with the argon content between 4.5 and 5%. The process cycle is almost similar to PSA air separation. The only difference is that here vacuum blowers are used to reduce the desorption pressure. Compared to a PSA, the lower desorption pressure reduces the required inlet pressure, as a result of which a typical oxygen VPSA produces oxygen is at 0.2 to 0.4 atmosphere, gauge. The system regenerates the sieve material under vacuum conditions and a higher percentage of available oxygen is recovered, and therefore less air has to be processed. Higher oxygen delivery pressures can be produced by adding an oxygen booster compressor to the VPSA system. The swing adsorption process in each of the two adsorbers consists of two stages running for a few minutes. At the adsorption stage Oxygen, H2O and CO2 molecules diffuse into the pore structure of the adsorbent whilst the nitrogen molecules are allowed to travel through the adsorberadsorbent-containing vessel. At the regeneration stage the adsorbed components are released from the adsorbent vented into the atmosphere. The process is then multiply repeated.VPSA Oxygen Generator (Product Description) A) Air fan and vacuum pump: Air fan provide air source for the whole system. Based on VPSA oxygen generator design condition and customer requirements fan with proper outlet air pressure is to be provided. Vacuum pump ensures correct system operation and keeps the system in ideal vacuum state, which ensures equipment constantly adsorb nitrogen and produce oxygen. B) Temperature regulating system: Air temperature regulating system is made up of a water cooler and an electric heater. The temperature of air compressed by fan is around 65-70 C, passing the water cooler, its temperature is reduced to meet the requirements of process operation. Then it is sent into the adsorption towers. In winter, the temperature of air is to be increased by the electric heater and reaches the requirements of process operation. C) Adsorption system: The adsorption system mainly consists of two towers filled with zeolite molecular sieve adsorbents and piping valves etc. Air enters into the bottom of one tower, when passing through the adsorbent layer, N2, oxygen, Vapor are adsorbed by molecular sieve and oxygen passes through the absorbents and gathers at the top of tower, flowing out as produced gas, meanwhile the other tower is in the process of regeneration. When the adsorbing tower almost reaches saturation, by the operation of control system, the processing air flows into the regenerated tower and begins to produce oxygen. Two towers alternately adsorb and constantly produce oxygen. D) Oxygen buffer tank: Compared with three-tower process, oxygen generator with two towers can not produce consecutive oxygen; therefore, a buffer tank with large volume is needed for stable oxygen output. E) Control system: System process is achieved by DCS control system. In this system, valves switches are independently controlled by PLC(Programmable Logic Controller). Analog signals of test sensors communicate with the main control system through specific communication protocols. Relevant data of specific unit can be sent to main control system and remote control signals of main control system can be accepted by specific unit. In order to ensure safe oxygen supply, functions of interlink, protection, alarm, print, record etc can be provided. The output variation of oxygen supply can be adjusted by DCS control system. System operating parameters can be adjusted to save energy. The main control system adopts industry computer, provided with specific software and convenient human-machine touching screen, Start/stop and operating parameter collection can be realized on control panel. Remote monitor and print of running status record can be easily achieved.