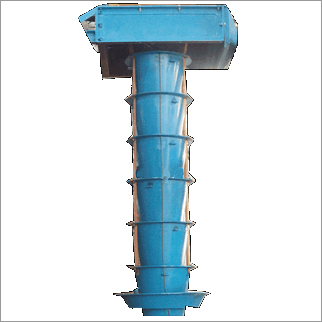

Vertical Raymond Mill Body Liner

Get LatestPrice

Get Best Deals

Wear debris contaminates products and is reassumed to be one cause of reduced brightness of the product. The main cause of the Problem...View Product Details

Product Overview

Key Features

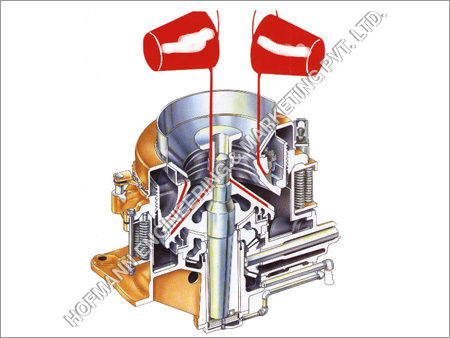

Wear debris contaminates products and is reassumed to be one cause of reduced brightness of the product. The main cause of the Problem is: Air transports (conveys ) the powdered product ground inside vertical mill. This causes severe erosion on the body liner. The resulted wear debris are conveyed along with the product. The Solution: The wear liners were selected with following MOC. a) Boiler quality base plate of 6mm overlaid with chromium carbide containing weld alloy of 4mm thickness. Weld alloy was Eutectic OA 4601 teromatic wire and was welded using REISS robot on a water-submerged plate. The deposited alloy had 56 HRC hardness.Though harder and more wear resistance carbides deposits were available; their use was restricted by the subsequent bending of wear liners to the fit the body. The inside geometry of the vertical mill body and the location of retaining holes were non-standard and varied on a mill-to-mill basis causing fitting delays. b) Packing material failure due to sleeve surface roughness. c) Mild steel plate of 10mm thickness was coated with Ni-Cr-B-Si alloy containing tungsten carbide to a concentration of around 50%. The deposit thickness was 0.4mm and hardness was around 60 HRC for the matrix and 850 Vickers for the carbide particles. Deposits were applied by the spray and fuse process and powder used was SF 15211/SF 10112 of Eutectic. Equipment by which spray had been done is Castodyn 8000 of Eutectic+Castolin Switzerland. The process is fast and plates can be bend to one desired shape without many efforts. Fitment is also relatively easy. The cost of providing the needed 0.8mm thick coating may be high.

Explore in hindi - वर्टिकल रेमंड मिल बॉडी लाइनर

Company Details

KEEPSAKE ENGINEERING CONSULTANCY PVT. LTD., Established in 1993 at Ahmedabad in Gujarat, is a leading service provider of Valves in India. KEEPSAKE ENGINEERING CONSULTANCY PVT. LTD. is one of Trade India's verified and trusted names for listed services. With extensive experience in the field of Valves, KEEPSAKE ENGINEERING CONSULTANCY PVT. LTD. has made a reputed name for itself in the market with satisfactory Carbide Hvof Coatings On Plunger, Chromium Oxide Coatings Flame, Hastalloy 2000 Coatings On Vessel, etc.

Focusing on a customer-centric approach, KEEPSAKE ENGINEERING CONSULTANCY PVT. LTD. has a pan-India presence and caters to a huge consumer base throughout the country. Get Valves from KEEPSAKE ENGINEERING CONSULTANCY PVT. LTD. at Trade India quality-assured services.

Focusing on a customer-centric approach, KEEPSAKE ENGINEERING CONSULTANCY PVT. LTD. has a pan-India presence and caters to a huge consumer base throughout the country. Get Valves from KEEPSAKE ENGINEERING CONSULTANCY PVT. LTD. at Trade India quality-assured services.

Business Type

Exporter, Manufacturer, Service Provider

Employee Count

18

Establishment

1993

Working Days

Monday To Saturday

GST NO

24AAACK7982Q1ZS

Payment Mode

Cheque

Seller Details

KEEPSAKE ENGINEERING CONSULTANCY PVT. LTD.

GST

24AAACK7982Q1ZS

Rating

5

Product Incharge

Mr. Nilesh Chudasama

Address

2, Meldi Industrial Estate, besides AEC substation, Near Railway Crossing, Gota, Ahmedabad, Gujarat, 382481, India

mill liners in AhmedabadReport incorrect details

Related Products

Aluminium Ball Mill Liner Plate Backing Compound

HOFMANN ENGINEERING & MARKETING PVT. LTD.

Ahmedabad, Gujarat

More Products From This Seller

Explore Related Categories

- Tradeindia

- Machinery & Parts

- Mill Liners

- Vertical Raymond Mill Body Liner In Gota

Recommended Products

Popular Products

Human HairForklift TrucksServo Voltage StabilizerBasmati RiceBackhoe LoaderCarry Bag Making MachineDrum LifterElectric StackerScissor LiftsIndustrial Vibrating ScreenRotameterFlowmeterRotary Air CompressorIndustrial Eto SterilizerRice Packaging MachinesShredding MachineHammer MillAutomatic Labelling MachineDiesel ForkliftAerial Work PlatformStorage Rack SystemEpoxy ResinMild Steel BarStainless Steel SheetsStainless Steel StripsBag Filling MachinesAsphalt PlantsSlat ConveyorOintment PlantPlanetary MixersLadies KurtisLed LightsCctv CameraBall ValveAnti Cancer MedicineAir CompressorIncense SticksSolar LightsGoods LiftsVitrified TilesStainless Steel CoilsPvc PipesPvc Pipe FittingsUpvc PipesUpvc Ball ValvePipe Elbows