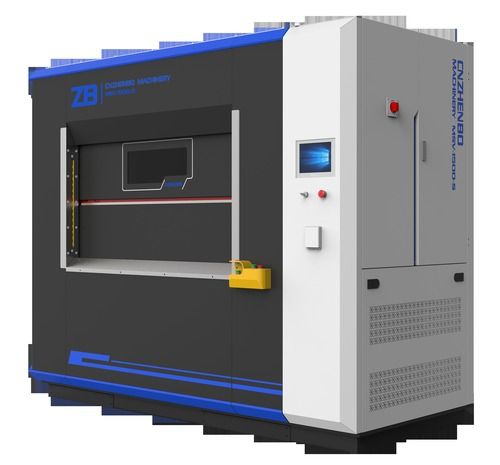

Servo Hot Plate Plastic Welder Air Pressure: 0.8 Mpa

Price: >1 USD

Get LatestPrice

| Automation | Automatic |

| Air Pressure | 0.8 mpa |

| Type | Vertical |

| Usage | Hot plate thermoplastic joining |

| Welding Area | 760*600(mm) |

Product Overview

Key Features

We are indulged in making, exporting, distributing and supplying Servo Hot Plate Plastic Welders in Wenzhou, Zhejiang, China. Servo hot plate welderMSH-8060S is designed to weld large thermoplastic by heating. Machine max welding square is 800*600 (mm), and effective welding square is 750*600 (mm). This hot plate welding machine tooling action forced by servo motors in high precision in 0.02mm.

Machine applies PLC to control action sequence. MP-SONIC deigned temperature controlling system control hot platen melting temperature in PID. Through change temperature control system, it can achieve non-contact plastic welding by infrared system. Machine control temperature by temperature modules of PLC. All machine parameters is set on HMI.

Basic Features:

1. Servo control system in high precision;

2. Fast action speed, especially good for low temperature hot platen welding;

3. Achieves action speed process control (speed-steps-control);

4. Hot platen melting temperature controlled by PID, welding temperature is controlled in stability and high precision;

5. Heater error ID is detected and indicated on HMI for easy fault-shooting;

6. Welding parameters storage is available to manage hot p late welding process;

7. Alarm message/fault history is recorded for hot plate welding quality management;

8. Optical fence at front and safety door at sides and rear is designed for security;

9. Vacuum generator and pneumatic clip system is design to hold plastic parts during hot plate welding;

10. Ejection function by pneumatic system is designed helping remove welded parts from jigs;

11. Parts detection function is available to avoid operation without parts loading.

Optional Feature:

1. Auto security front door;

2. Auto jig loading system for quick tooling change-over;

3. Preheating device for efficient welding production;

4. SPC for production management;

5. E-tech for internet;

6. Terminal for printer;

7. Auto electrical plugs and air connectors for jig;

8. Tooling automatic identifying to identify hot plate welding and load welding parameter automatically;

9. UPS for control system;

10. Vacuum pump for high vacuum pressure;

11. Accessories detection to avoid welding unloading small parts;

12. GT sensor function to ensure parts is loaded in right position before operation for plastic welding in high precision.

Specification:

1. Power Source: 380V 3P 50/60Hz

2. Air Source: 0.5Mp;

3. Dimension:L1550*W2200*H2562 (mm);

4. Jig Base Plate: 880*650

5. Suggested Welding Square: <750*600 (mm)

6. Welding Square: 800*600(mm)

7. Jig Transmission: High Precision Screw Bar;

8. Hot Platen Transmission: Gear Bar;

9. Clips: 4+4;

11. Accessory Detector on Jig: 6+6

12. Cavity Parts Detector: 2+2

13. Temperature Control: 8 Sets

14. SafetyA A A Optical fence + Auto front door

15. Vacuum: Vacuum Generator

16. Cooling for Control Cabinet: Fan

17. Smoke Exhaust: Exhaust Fan

18. Heating Alarm: Heating current supervision and alarm

Machine applies PLC to control action sequence. MP-SONIC deigned temperature controlling system control hot platen melting temperature in PID. Through change temperature control system, it can achieve non-contact plastic welding by infrared system. Machine control temperature by temperature modules of PLC. All machine parameters is set on HMI.

Basic Features:

1. Servo control system in high precision;

2. Fast action speed, especially good for low temperature hot platen welding;

3. Achieves action speed process control (speed-steps-control);

4. Hot platen melting temperature controlled by PID, welding temperature is controlled in stability and high precision;

5. Heater error ID is detected and indicated on HMI for easy fault-shooting;

6. Welding parameters storage is available to manage hot p late welding process;

7. Alarm message/fault history is recorded for hot plate welding quality management;

8. Optical fence at front and safety door at sides and rear is designed for security;

9. Vacuum generator and pneumatic clip system is design to hold plastic parts during hot plate welding;

10. Ejection function by pneumatic system is designed helping remove welded parts from jigs;

11. Parts detection function is available to avoid operation without parts loading.

Optional Feature:

1. Auto security front door;

2. Auto jig loading system for quick tooling change-over;

3. Preheating device for efficient welding production;

4. SPC for production management;

5. E-tech for internet;

6. Terminal for printer;

7. Auto electrical plugs and air connectors for jig;

8. Tooling automatic identifying to identify hot plate welding and load welding parameter automatically;

9. UPS for control system;

10. Vacuum pump for high vacuum pressure;

11. Accessories detection to avoid welding unloading small parts;

12. GT sensor function to ensure parts is loaded in right position before operation for plastic welding in high precision.

Specification:

1. Power Source: 380V 3P 50/60Hz

2. Air Source: 0.5Mp;

3. Dimension:L1550*W2200*H2562 (mm);

4. Jig Base Plate: 880*650

5. Suggested Welding Square: <750*600 (mm)

6. Welding Square: 800*600(mm)

7. Jig Transmission: High Precision Screw Bar;

8. Hot Platen Transmission: Gear Bar;

9. Clips: 4+4;

11. Accessory Detector on Jig: 6+6

12. Cavity Parts Detector: 2+2

13. Temperature Control: 8 Sets

14. SafetyA A A Optical fence + Auto front door

15. Vacuum: Vacuum Generator

16. Cooling for Control Cabinet: Fan

17. Smoke Exhaust: Exhaust Fan

18. Heating Alarm: Heating current supervision and alarm

Product Specifications

| Automation | Automatic |

| Air Pressure | 0.8 mpa |

| Type | Vertical |

| Usage | Hot plate thermoplastic joining |

| Welding Area | 760*600(mm) |

| Dimension (L*W*H) | L1550*W2200*H2562 Millimeter (mm) |

| Power | 50K Watt (w) |

| Voltage | 380 Volt (v) |

| Weight | 2000 Kilograms (kg) |

| Control System | Simensi |

| FOB Port | Ningbo |

| Supply Ability | 1000sets Per Year |

| Delivery Time | 50 Days |

| Packaging Details | Wooden Case |

| Main Export Market(s) | Western Europe, Australia, South America, Eastern Europe, Middle East, Central America, Asia |

| Main Domestic Market | All India |

| Certifications | ISO & CE & SGS |

Explore in hindi - सर्वो हॉट प्लेट प्लास्टिक वेल्डर

Company Details

Zhejiang Zhenbo Precision Machinery Co.,Ltd is the manufacturing factory of MP-SONIC set in China in 2012. MP-SONIC is a company set since 2006 devoted the R & D the procedure and equipment for plastic welding & cutting, including the principle by ultrasonic, vibration, laser, hot plate, infrared, spin, etc. Now MP-SONIC is well-know all over the world for its high welding & cutting technology and stable machine quality.

Zhenbo (MP-SONIC. China) takes up 4000 SQM for production plant in Wenzhou City of Zhenjiang province. We have our Commercial office center in Shanghai international city. And a new factory taking up 8000SQM is under building.

We have strong designers and engineers to analyze customer's product 3D date, specification and materials, and offer technical suggestions and do feasibility report for choosing best suitable welding technology and giving best answer results. We also build a research lab to develop welding technology and give our best support to our designers and engineers team.

Now we provides vibration welders, ultrasonic plastic / metal welder, Laser plastic welder, infrared plastic welder, SMP machines, spin welder, multiple welding machines, plastic cutting/punching system, etc to domestic and oversea markets.

Our projects from our clients are mostly complicated, such as instrument panels, dashboards, rear lamps in Auto industry and other home appliance industry.

In the future we would like to work with our regular and new clients around world, and to create more values with our improvement in technology, reliable products and good service.

Business Type

Exporter, Manufacturer, Supplier

Employee Count

50

Establishment

2012

Working Days

Monday To Sunday

Payment Mode

Cash Against Delivery (CAD)

Seller Details

Zhejiang Zhenbo Precision Machinery Co. Ltd.

Rating

4

Commercial Director

Mr Alex Lee

Address

No 289, Weiqi Road, Yueqing Economic Development Zone, Wenzhou, Zhejiang, 913303025905963412, China

hot plate welder in WenzhouReport incorrect details

Related Products

Mild Steel High End Hot Plate Welders

RAVIRA EVERGREEN ULTRASONIC SYSTEMS PVT. LTD.

Mumbai, Maharashtra

Hot Plate Welder Dimensions: 1350 X 1300 X 2250 Millimeter (Mm)

MOQ - 1 Unit/Units

AXESS ULTRASONICS PVT. LTD.

Ghaziabad, Uttar Pradesh

More Products From This Seller

Explore Related Categories

- Tradeindia

- Welding Equipment

- Hot Plate Welder

- Servo Hot Plate Plastic Welder In Yueqing Economic Development Zone

Popular Products

Human HairForklift TrucksServo Voltage StabilizerBasmati RiceBackhoe LoaderCarry Bag Making MachineDrum LifterElectric StackerScissor LiftsIndustrial Vibrating ScreenRotameterFlowmeterRotary Air CompressorIndustrial Eto SterilizerRice Packaging MachinesShredding MachineHammer MillAutomatic Labelling MachineDiesel ForkliftAerial Work PlatformStorage Rack SystemEpoxy ResinMild Steel BarStainless Steel SheetsStainless Steel StripsBag Filling MachinesAsphalt PlantsSlat ConveyorOintment PlantPlanetary MixersLadies KurtisLed LightsCctv CameraBall ValveAnti Cancer MedicineAir CompressorIncense SticksSolar LightsGoods LiftsVitrified TilesStainless Steel CoilsPvc PipesPvc Pipe FittingsUpvc PipesUpvc Ball ValvePipe Elbows